Wall Prototype #1: FGF Additive Manufactured Assembly

Wall Prototype #1: FGF Additive Manufactured Assembly

/Large-Format Additively Manufactured Wall System

Description coming soon….

Lead Researcher: Robert Stuart-Smith

Researchers: Renhu (Franklin) Wu, Simone Yang

Siteless House: DFD Precast Concrete House

/SITELESS HOUSE: DFD PRECAST CONCRETE HOUSE

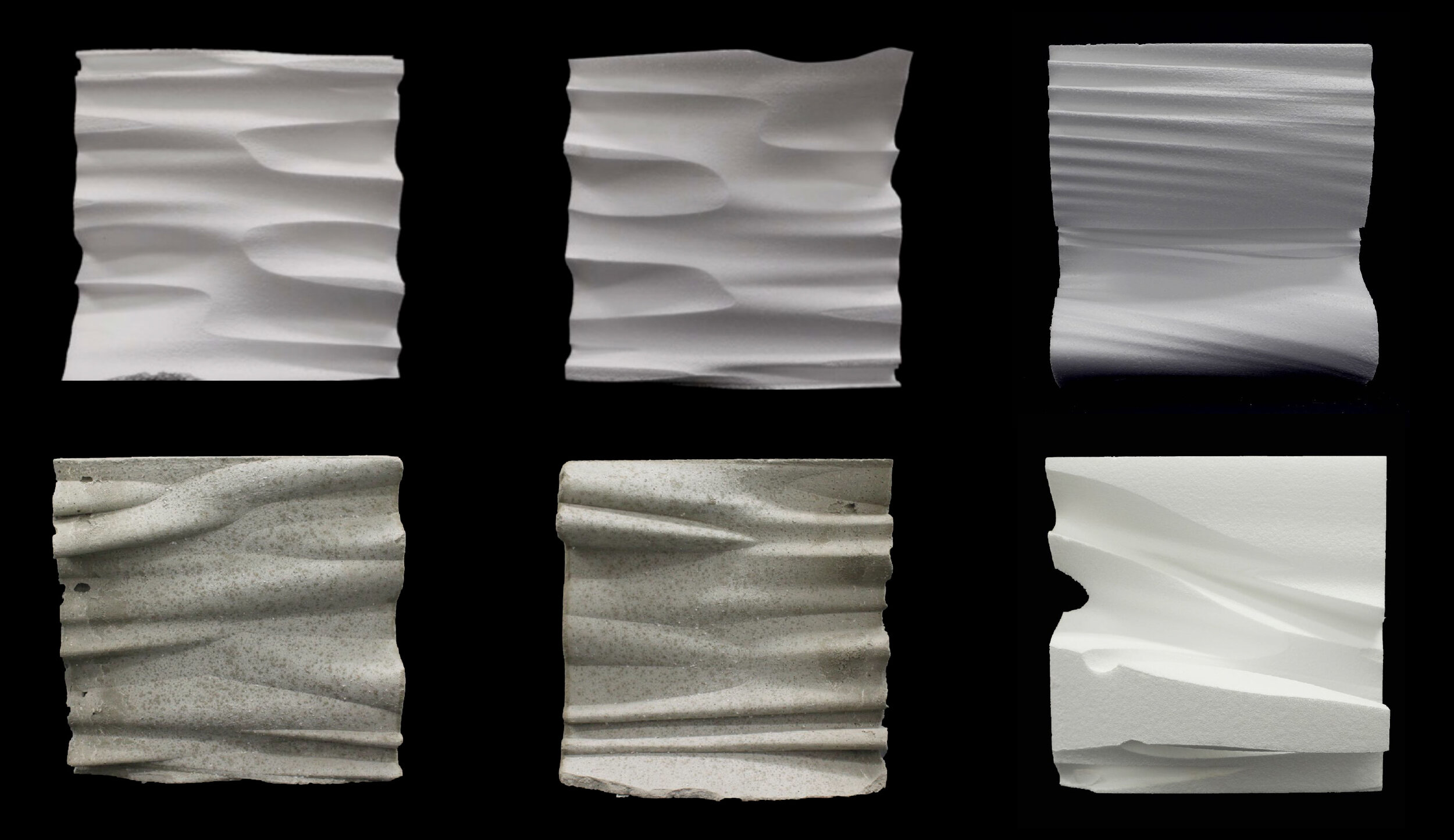

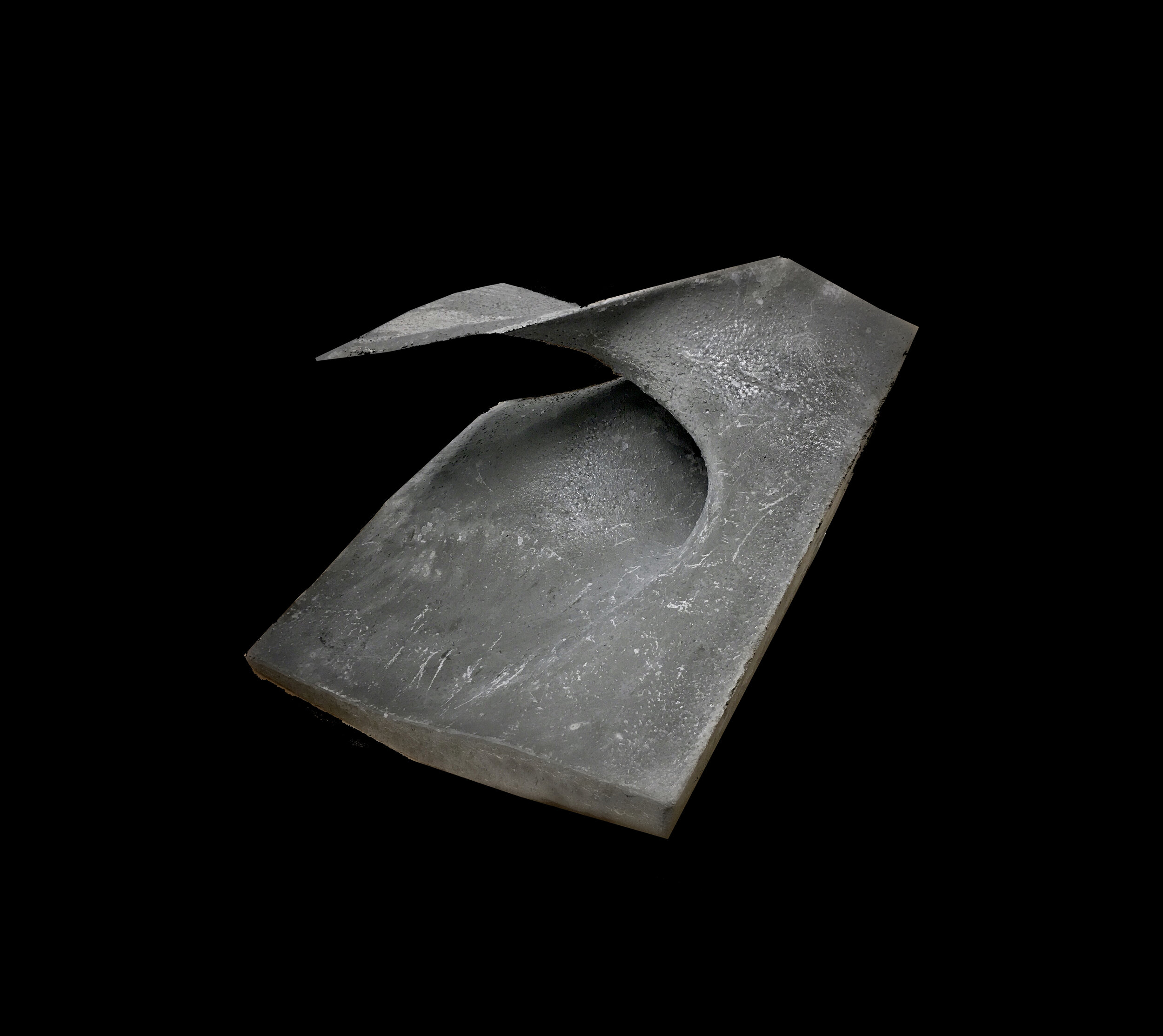

Advanced robotic fabrication and design-computation for precast self-compacting concrete

Collaborating Partner: Cemex Global R&D

Siteless House explores an alternative approach to relocatable housing through the development of a new type of Design-For-Disassembly (DFD) light-weight precast concrete tectonic that operates as a structural building envelope with integrated floor and foundations. A design-computation and fabrication method for robot hot-wire cutting of expanded polystyrene (EPS foam) is being developed to enable the design and engineering of light-weight high-strength loose-fibre reinforced precast concrete building component parts. Each part is able to be produced with a variable geometrical form and surface articulation in order to further increase the material efficiency of each part, while exploring scale-free modes of architectural design expression. The project is on-going with a full-size prototype house planned for construction in the next academic year.

Penn Research Lead: Robert Stuart-Smith and Masoud Akbarzadeh.

Cemex Global R&D Research Lead: Vice President Davide Zampini.

Penn Researchers: Mahsa Masalegoo, Bowen Qin, Mariana Righi, David Forero, Riley Studebaker, Yi Dazhong, Yuxuan Wang, Jiangson Yuan, Emma Peng, Musab Badahdah, Ian Pangburn.

Cemex Global R&D Researchers: Alexandre Guerini, Carlos Enrique Terrado, Valentina Rizzo, Matthew Meyers.

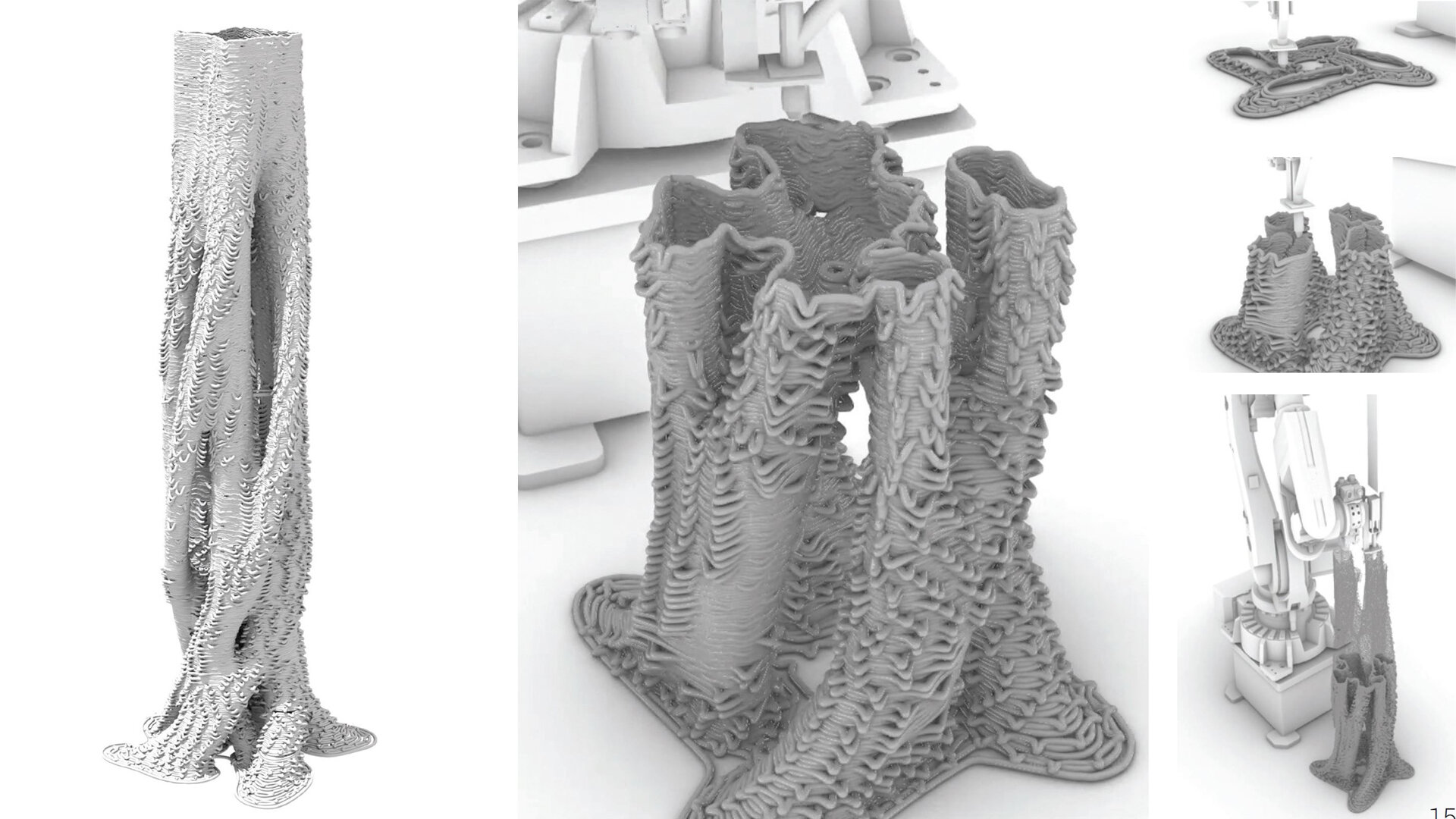

matForm Ceramic Columns: Agent-based Additive Manufacturing

/matForm Ceramic Columns: Agent-based Additive Manufacturing

Prototypical Column Geometries Additively Manufactured by Agent-based robotic extrusion

Description coming soon….

Lead Researcher: Robert Stuart-Smith

Researchers: Renhu (Franklin) Wu, Patrick Danahy, Natalia Revelo, Sanjana Rao

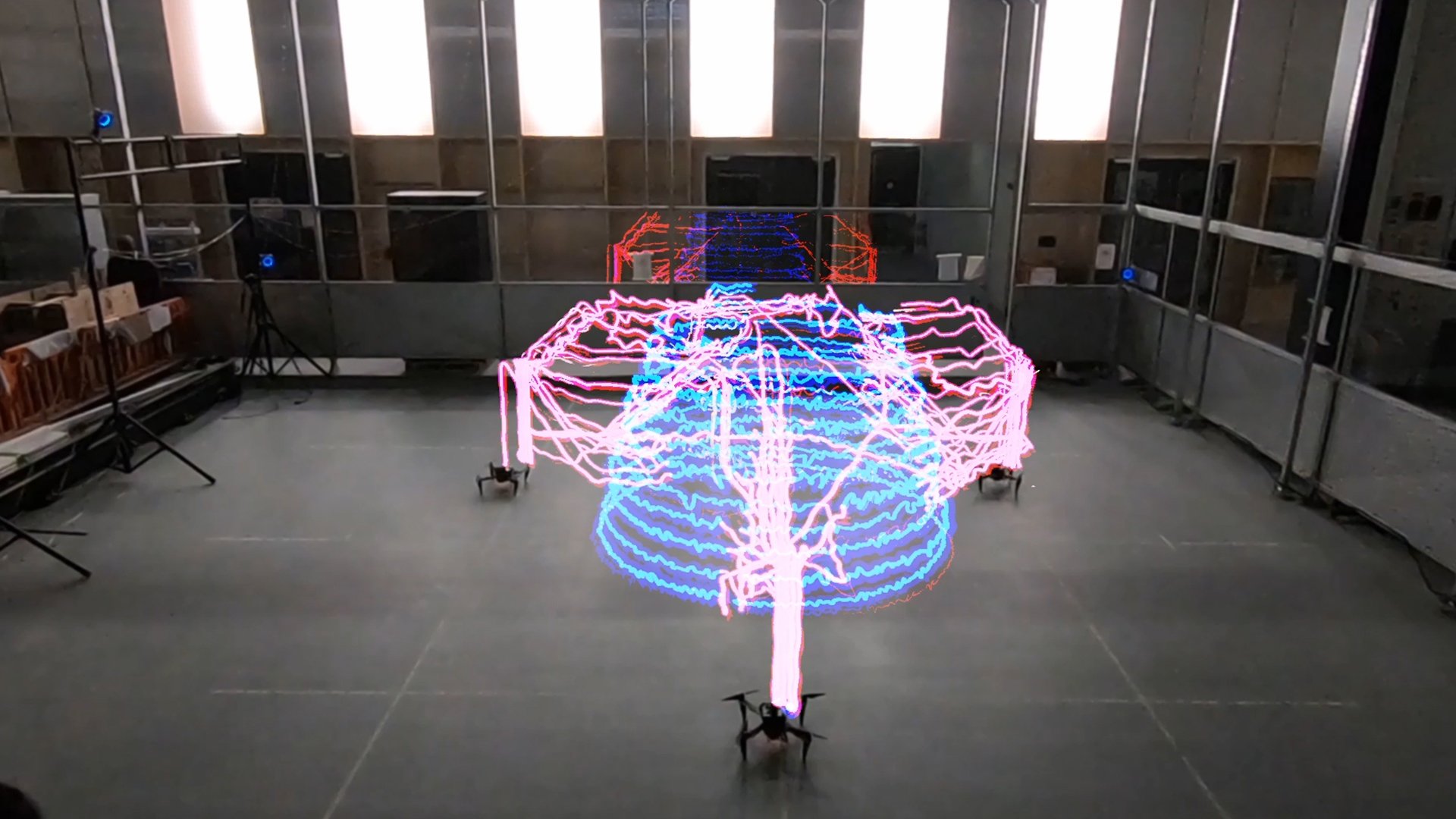

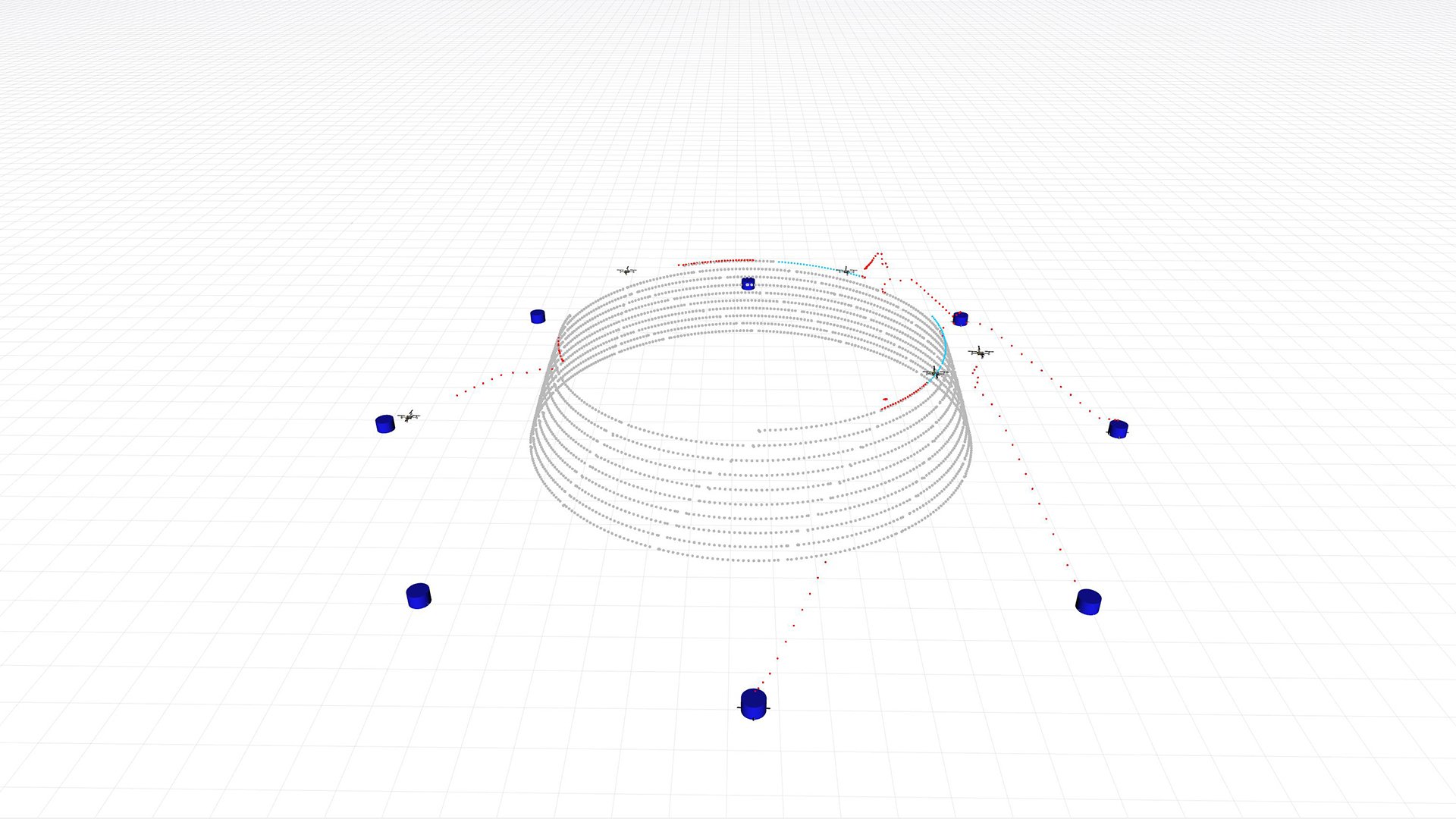

Aerial Additive Manufacturing (AML-Penn & AML-UCL)

/AERIAL ADDITIVE MANUFACTURING (AERIAL AM)

Additive manufacturing methods using static and mobile robots are being developed for both on-site construction and off-site prefabrication. Here we introduce a method of additive manufacturing, referred to as aerial additive manufacturing (Aerial-AM), that utilizes a team of aerial robots inspired by natural builders such as wasps who use collective building methods. We present a scalable multi-robot three-dimensional (3D) printing and path-planning framework that enables robot tasks and population size to be adapted to variations in print geometry throughout a building mission. The multi-robot manufacturing framework allows for autonomous three-dimensional printing under human supervision, real-time assessment of printed geometry and robot behavioural adaptation. Aerial-AM allows manufacturing in-flight and offers future possibilities for building in unbounded, at-height or hard-to-access locations.

Research Team:

Research Leaders: Mirko Kovac (PI), Robert Stuart-Smith (Co-I), Stefan Leutenegger (Co-I), Vijay Pawar (Co-I), Richard Ball (Co-I), Chris Williams (Co-I) and Paul Shephard (Co-I), and their respective research teams at Imperial College, University College London, University of Bath, University of Pennsylvania, Queen Mary University, and University of Munich.

Researchers: Zhang, K., Chermprayong, P., Xiao, F., Tzoumanikas, D., Dams, B., Kay, S., Kocer, B. B., Burns, A., Orr, L., Choi, C., Darekar, D. D., Li, W., Hirschmann, S., Soana, V., Ngah, S. A., Sareh, S., Choubey, A

Industrial Adivsors:

Cementation Skanska, Burohappold, Ultimaker, BRE

Image Credits:

Aerial AM Cementitious 3d print using a custom buildDrone with a delta-arm manipulator. Aerial Robotics Lab, Imperial college.

Aerial AM foam 3d print. Sarah Lever photography. Autonomous Manufacturing lab, UCL.

Timelapse light trace demonstrating multi-agent coordination of Aerial AM robot team. Autonomous Manufacturing lab, UCL

Multi-Agent Aerial AM Simulations. Autonomous Manufacturing lab, University of Pennsylvania

Aerial AM Tower

/Aerial AM Tower

Aerial Additive Manufacturing (Aerial AM)

The construction industry is adopting additive manufacturing (AM) technologies for onsite construction due to their ability to reduce the time and cost of building. On-site AM typically involves the continuous extrusion of horizontal layers of material using a gantry, larger than the build volume, to move a single extruder mechanism. Transporting and installing such gantry systems limits AM to easily accessible sites. In contrast, Aerial AM, enables swarm-based, parallel manufacturing in remote, or hard-to-access locations, providing greater flexibility and boundless manufacturing. Having recently published in Nature a demonstration of the world’s first Aerial AM with cementitious and composite materials in-flight, Aerial AM Tower is a speculative project that explores the potential of an aerial additively manufactured architecture of near-infinite height. The project’s structural concept (Anders et al. 2019), together with the logistical and aesthetic possibilities of an unbounded swarm-constructed architecture are based on research proofs of concept (Zhang et al, 2022; Stuart-Smith et al, 2023). A custom algorithm produces a structurally efficient concrete tower geometry of 2km in height, whose topological complexity and inclination would be infeasible to construct by traditional building or gantry-based AM approaches. Unbounded, Aerial AM is theoretically able to construct the tower as a filagree exoskeleton, partially designed through the act of construction without support scaffolds. A simulated swarm of aerial robots collectively builds, self-organizing as they move upwards along the surface of a virtual model of the tower. The intricate geometry of the exoskeleton arises from aerial robot agent-to-agent local interactions, resulting in an emergent exoskeleton formation that is intrinsic to the structural geometry of the tower and the act of aerial swarm construction.

Lead Researcher: Robert Stuart-Smith

Lead Collaborators: Chris Williams (Uni Bath), Paul Shepherd (Uni Bath), Vijay Pawar (UCL), Mirko Kovac (Imperial College / Empa)

Researchers: Andrew Homick Patrick Danahy

Associated Research Papers:

Ander, M., P. Shepard, R.Stuart-Smith, and C.Williams. “A building of unlimited height”. In Proceedings of the IASS Annual Symposium 2019 - Structural Membranes 2019: Form and Force, edited by C. Lázaro, K.-U. Bletzinger, and E. Onate (Eds.), International Association for Shell and Spatial Structures (IASS), Barcelona, 2019, 1426-1433

Stuart-Smith, R., D. Darekar, P. Danahy, B. Bahadir Kocer, V. Pawar, and M. Kovac. “Collective Aerial Additive Manufacturing.” In Proceedings of the 42nd Annual Conference of the Association of Computer Aided Design in Architecture (ACADIA), edited by M. Akbarzadeh, D. Aviv, H. Jamelle, and R. Stuart-Smith, 44-55. La Vergne: IngramSpark, 2023.

Stuart-Smith, R., M. Kovac, V. Pawar, C. Williams, and P. Shepard. “Aerial Additive Manufacturing” (Aerial AM). In Time, Space, Existence: Venice 2023 Architecture Biennial, edited by European Cultural Centre Team, 474-475. Amsterdam: European Cultural Centre, 2023.

Zhang, K., P. Chermprayong, F. Xiao, D. Tzoumanikas, B. Dams, S. Kay, B.B. Kocer, A. Burns, L. Orr, T. Alhinai, C. Choi, D.D. Darekar, W. Li, S. Hirschmann, V. Soana, S.A. Ngah, C. Grillot, S. Sareh, A. Choubey, R. Stuart-Smith and M. Kovac, et al. “Aerial Additive Manufacturing with Multiple Autonomous Robots.” Nature 609, no. 7928, 2022: 709-717. DOI. https://doi.org/10.1038/s41586-022-04988-4.

Visceral/L Pavilion

/VISCERAL/L

Text description coming soon….

Lead Researcher: Robert Stuart-Smith

Researchers: Patrick Danahy

Visceral/L Autonomous Sculpting

/VISCERAL/L Autonomous Sculpting

Text description coming soon….

Lead Researcher: Robert Stuart-Smith

Researchers: Riley Studebaker

Aerial AM Shell

/Aerial AM Shell

Aerial Additive Manufacturing (Aerial AM)

The construction industry is adopting additive manufacturing (AM) technologies for onsite construction due to their ability to reduce the time and cost of building. On-site AM typically involves the continuous extrusion of horizontal layers of material using a gantry, larger than the build volume, to move a single extruder mechanism. Transporting and installing such gantry systems limits AM to easily accessible sites. In contrast, Aerial AM, enables swarm-based, parallel manufacturing in remote, or hard-to-access locations, providing greater flexibility and boundless manufacturing. Having recently published in Nature a demonstration of the world’s first Aerial AM with cementitious and composite materials in-flight, Aerial AM Shell is a speculative project that explores the potential of an aerial additively manufactured architecture that is realizable without the use of temporary scaffolding.

Aerial AM Shell (AAMS)

Most AM building designs are constrained to vertically extruded geometries, with floors or roofs constructed by other means, which limits building automation and material efficiencies achievable in monolithic free-form geometries such as funicular shell structures. Shells provide long-spanning spatial enclosure with a minimal amount of material, yet require support scaffolding during construction. Although less efficient than a funicular shell, AAMS is realizable without temporary supports. A shell geometry is reinforced throughout construction with ridging, trussing, and vertical props in regions of high structural deflection or shallow inclination identified by frequent analysis in-the-loop. The design is developed through a multi-agent simulation within the Aerial AM software framework, aligning it with actual real-time design and construction workflows. Its incremental swarm-building approach opens possibilities for adaptive or regenerative building, where architecture might be realized through acts of continuous construction or modification over time.

Lead Researcher: Robert Stuart-Smith

Lead Collaborators: Vijay Pawar (UCL), Mirko Kovac (Imperial College / Empa)

Researchers: Patrick Danahy

Associated Research Papers:

Stuart-Smith, R., D. Darekar, P. Danahy, B. Bahadir Kocer, V. Pawar, and M. Kovac. “Collective Aerial Additive Manufacturing.” In Proceedings of the 42nd Annual Conference of the Association of Computer Aided Design in Architecture (ACADIA), edited by M. Akbarzadeh, D. Aviv, H. Jamelle, and R. Stuart-Smith, 44-55. La Vergne: IngramSpark, 2023.

Stuart-Smith, R., M. Kovac, V. Pawar, C. Williams, and P. Shepard. “Aerial Additive Manufacturing” (Aerial AM). In Time, Space, Existence: Venice 2023 Architecture Biennial, edited by European Cultural Centre Team, 474-475. Amsterdam: European Cultural Centre, 2023.

Zhang, K., P. Chermprayong, F. Xiao, D. Tzoumanikas, B. Dams, S. Kay, B.B. Kocer, A. Burns, L. Orr, T. Alhinai, C. Choi, D.D. Darekar, W. Li, S. Hirschmann, V. Soana, S.A. Ngah, C. Grillot, S. Sareh, A. Choubey, R. Stuart-Smith and M. Kovac, et al. “Aerial Additive Manufacturing with Multiple Autonomous Robots.” Nature 609, no. 7928, 2022: 709-717. DOI. https://doi.org/10.1038/s41586-022-04988-4.

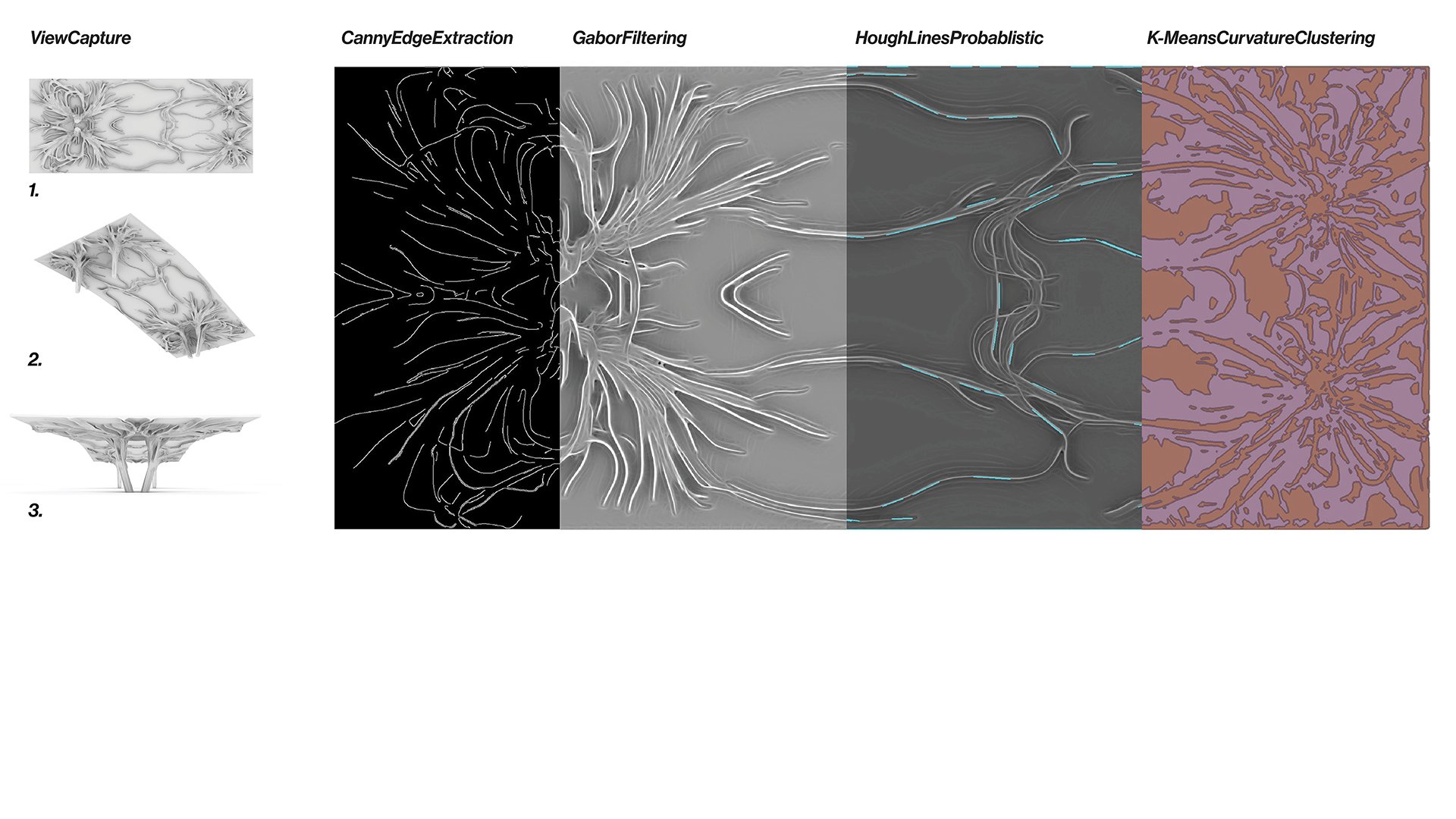

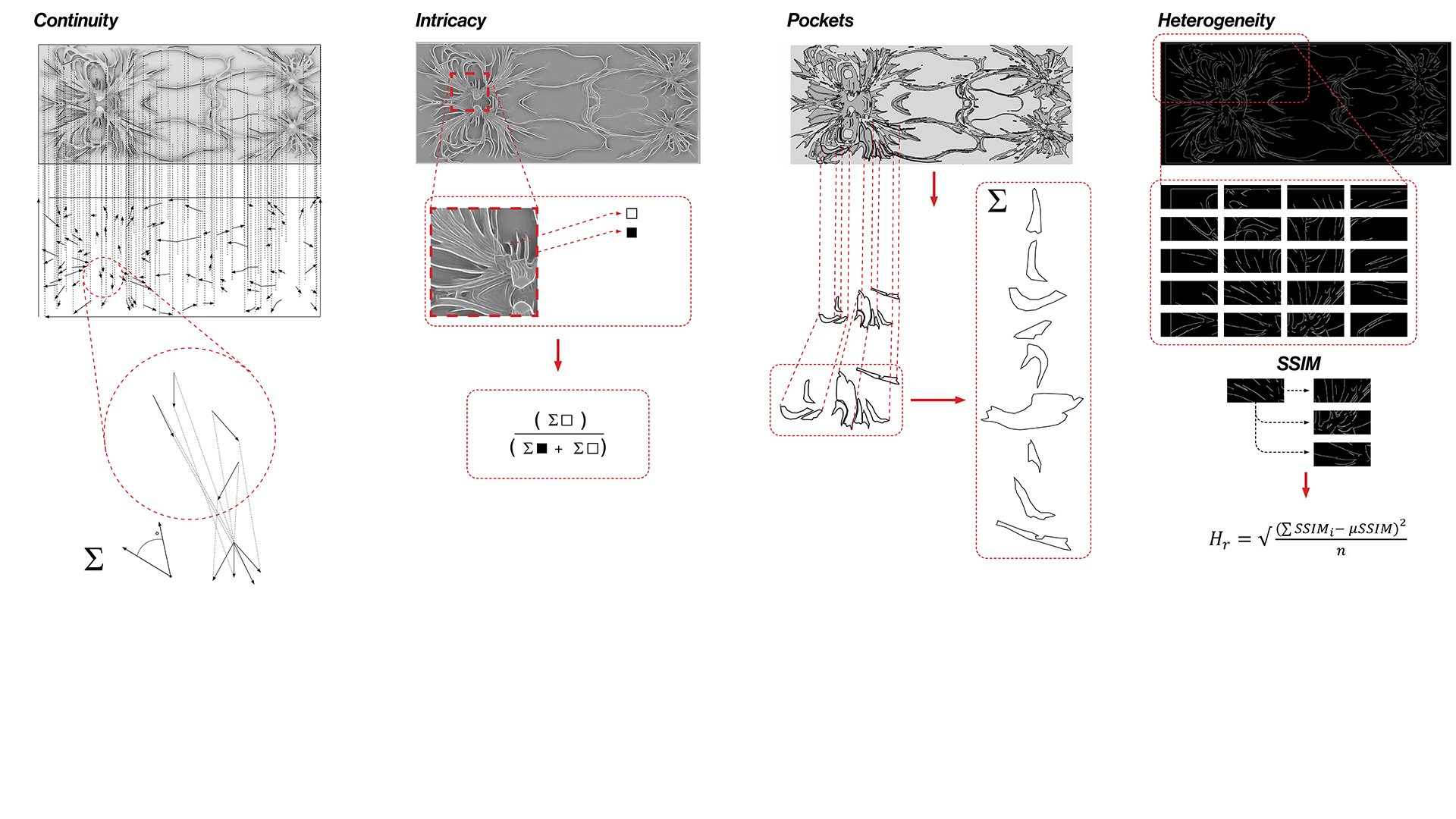

Visual Character Analysis for Algorithmic Building Design

/VISUAL CHARACTER ANALYSIS FOR ALGORITHMIC BUILDING DESIGN

Buildings are responsible for 40% of world C02 emissions and 40% of the world's raw material consumption. Designing buildings with a reduced material volume is essential to securing a post-carbon built environment and supports a more affordable, accessible architecture. Architecture’s material efficiency is correlated to structural efficiency however, buildings are seldom optimal structures. Architects must resolve several conflicting design criteria that can take precedence over structural concerns, while material-optimization is also impacted from limited means to quantitatively assess aesthetic decisions. A novel approach to quantitative analysis of visual formal character. Computer vision methods Gabor filtering, Canny Contouring and others are utilized to evaluate the visual appearance of designs and encode these within quantitative metrics. A matrix of design outcomes for a pavilion were utilized to evaluate visual character relative to structural, and geometric methods of analysis and demonstrate a limited set of aesthetic design criteria can be correlated with structural and geometric data in a quantitative metric.

Lead Researcher: Robert Stuart-Smith

Researchers: Patrick Danahy

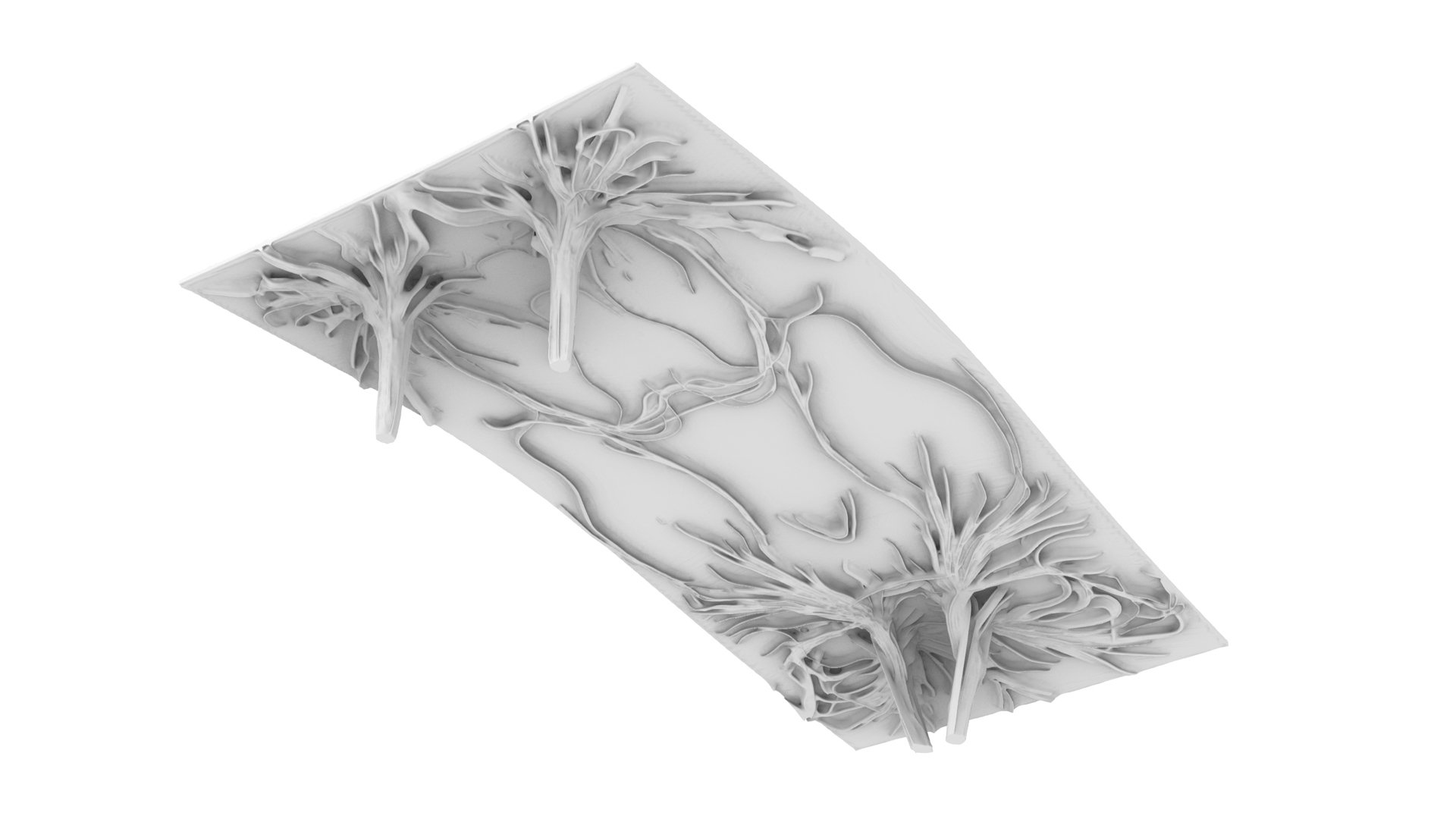

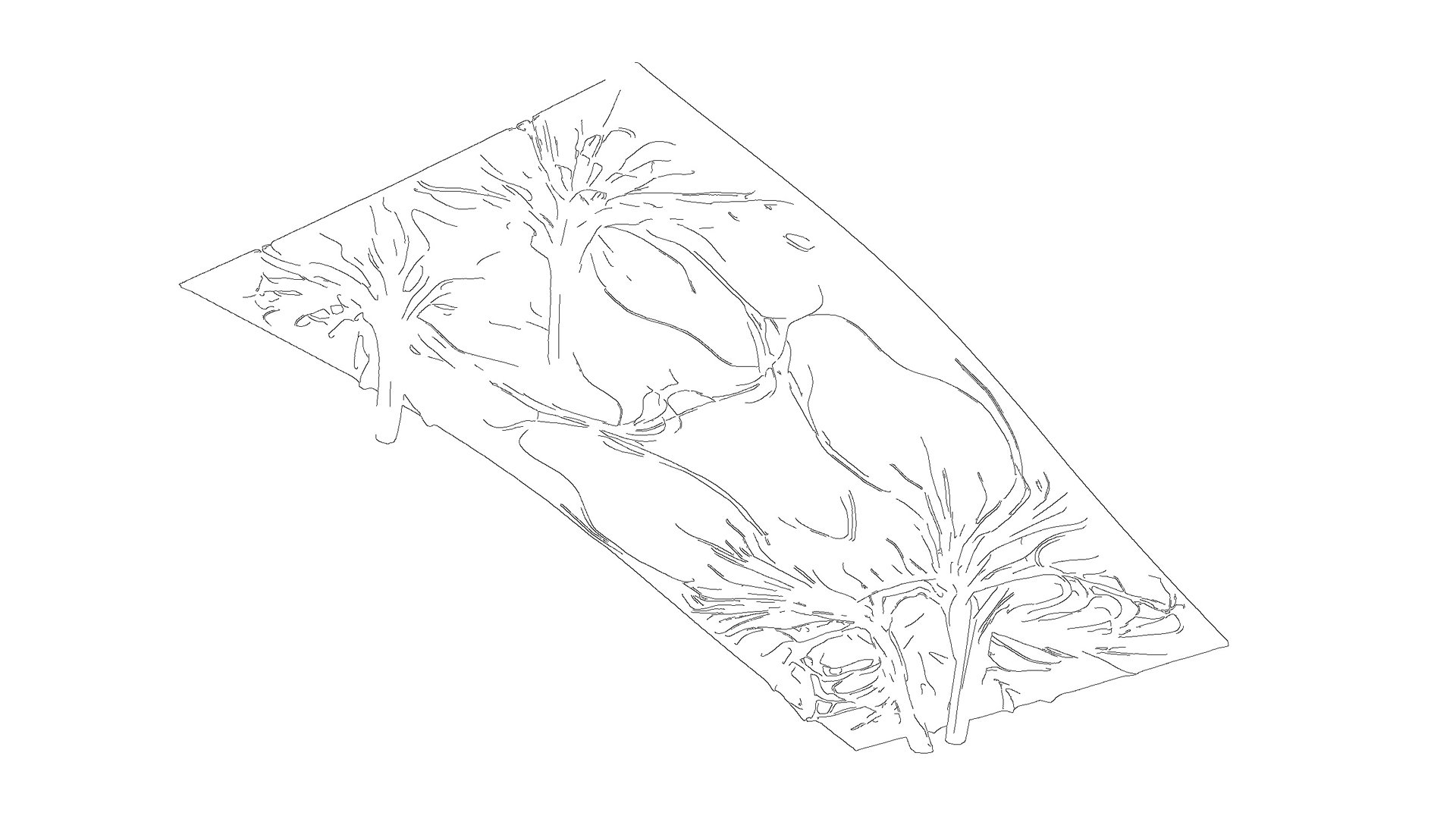

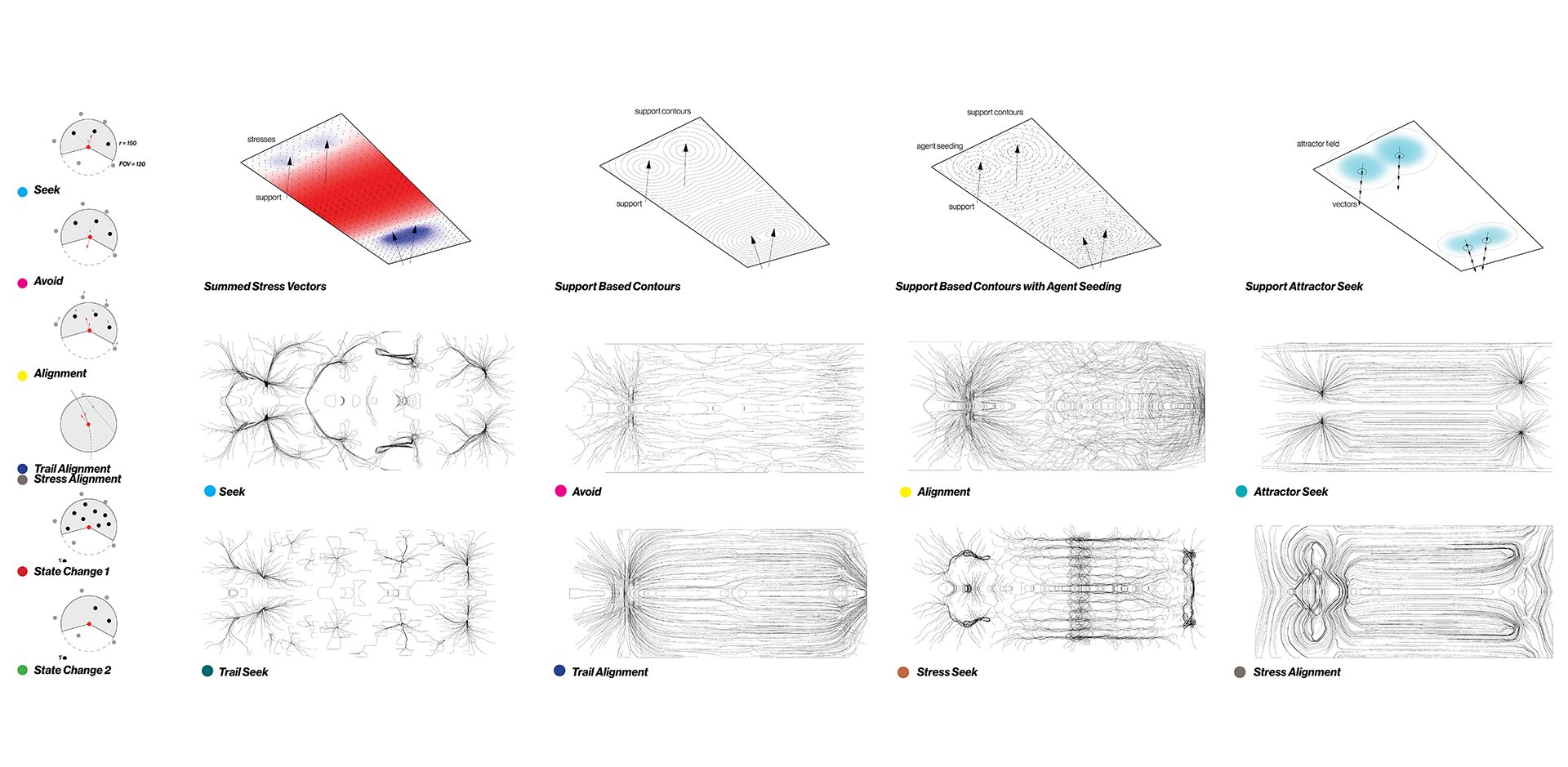

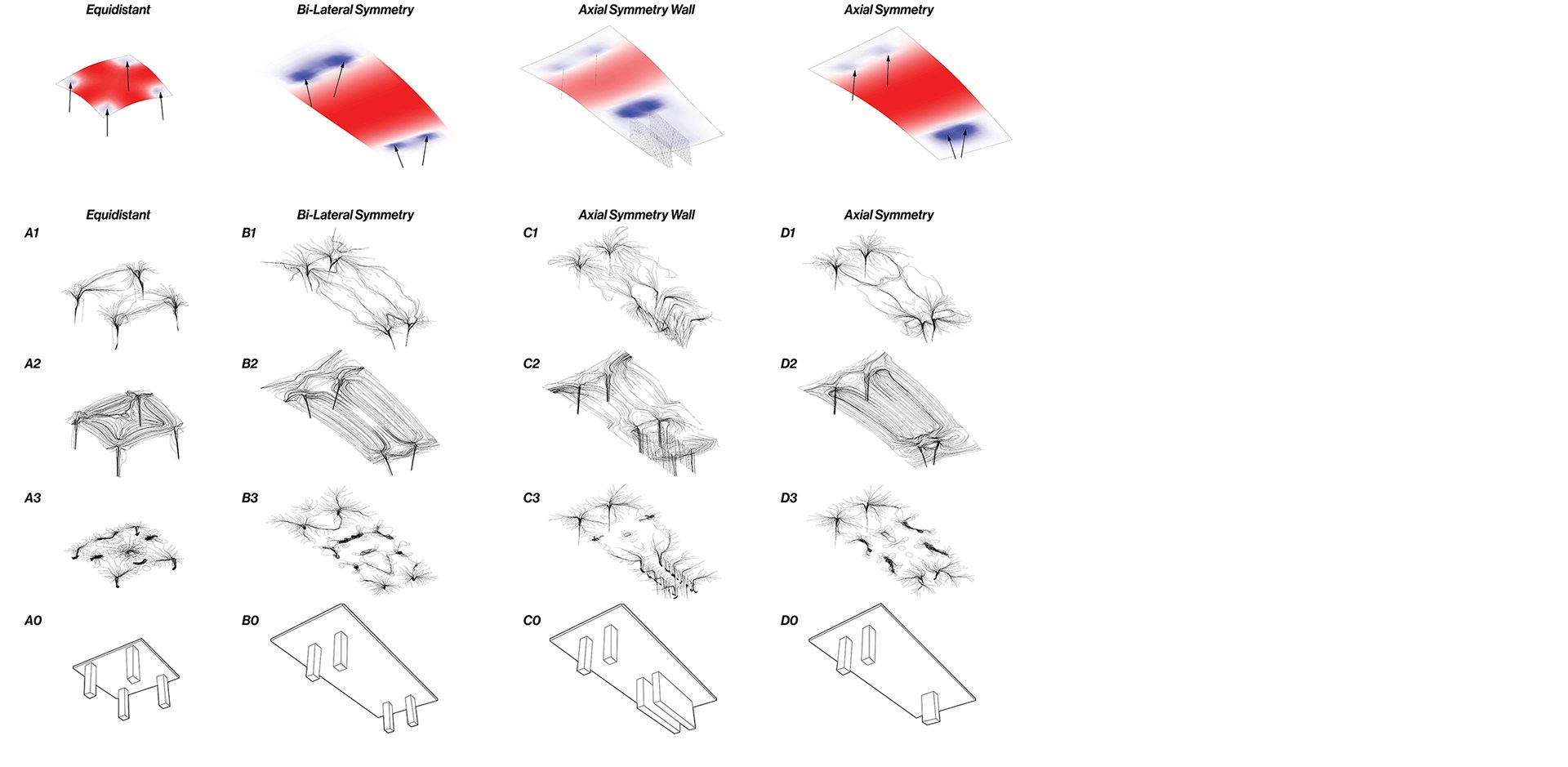

topoForm#2: Generative Topological Design for Additive Manufacturing

/MULTI-AGENT TOPOLOGICAL FORMATION FOR ADDITIVE MANUFACTURING

Buildings are responsible for 40% of world C02 emissions and 40% of the world's raw material consumption. Designing buildings with a reduced material volume is essential to securing a post-carbon built environment and supports a more affordable, accessible architecture. Architecture’s material efficiency is correlated to structural efficiency however, buildings are seldom optimal structures. Flexible design methods are required that can adapt to diverse constraints and generate filagree material arrangements, currently infeasible to explicitly model. A novel approach to generative topological design is proposed employing a custom multi-agent method that is adaptive to diverse structural conditions. This research develops multi-manifold topological design solutions tailored to additive manufactured production, where additional geometric complexity is leveraged to minimise material volume, while addressing architectural expression.

Lead Researcher: Robert Stuart-Smith

Researchers: Patrick Danahy, David Forero

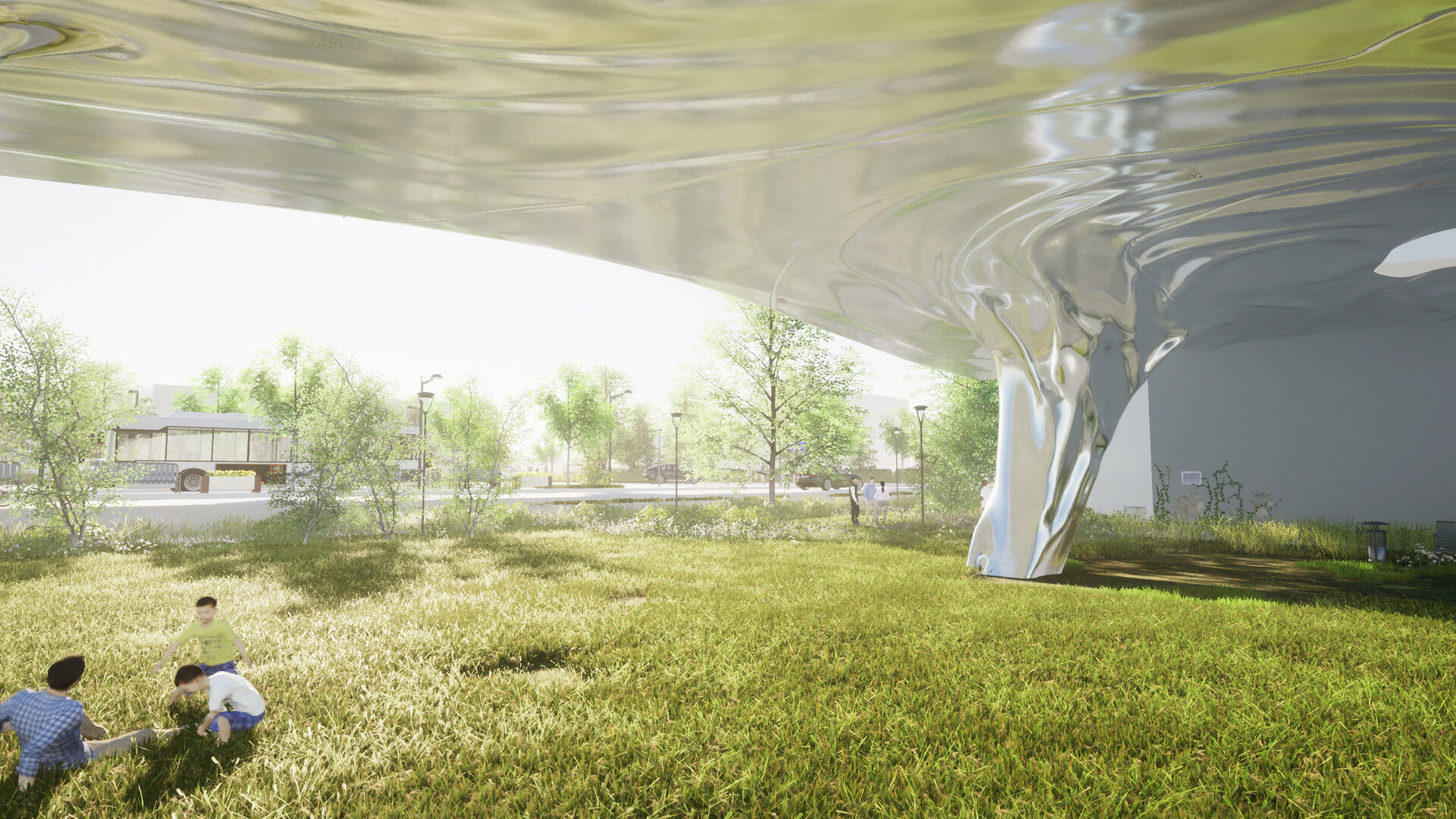

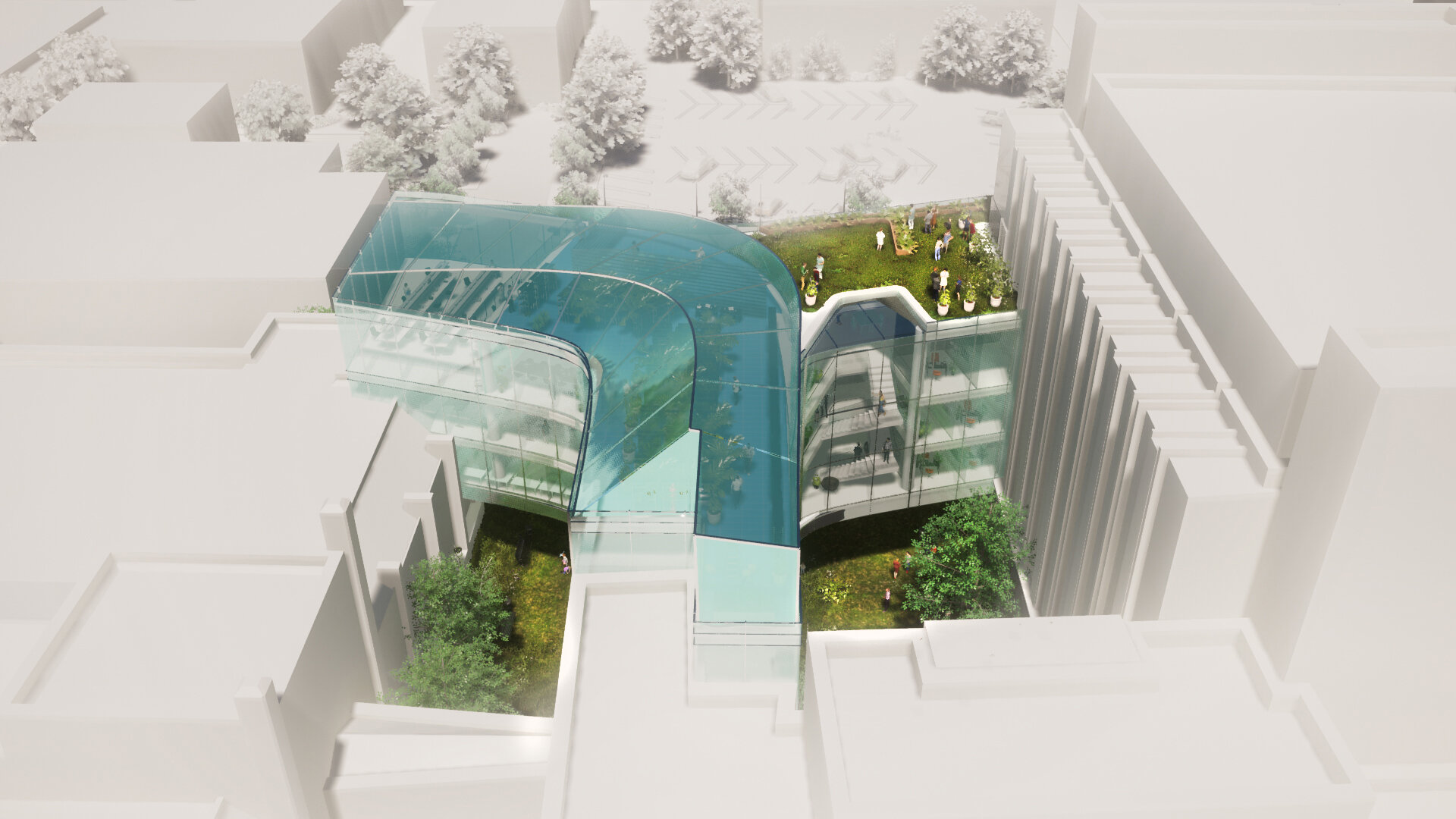

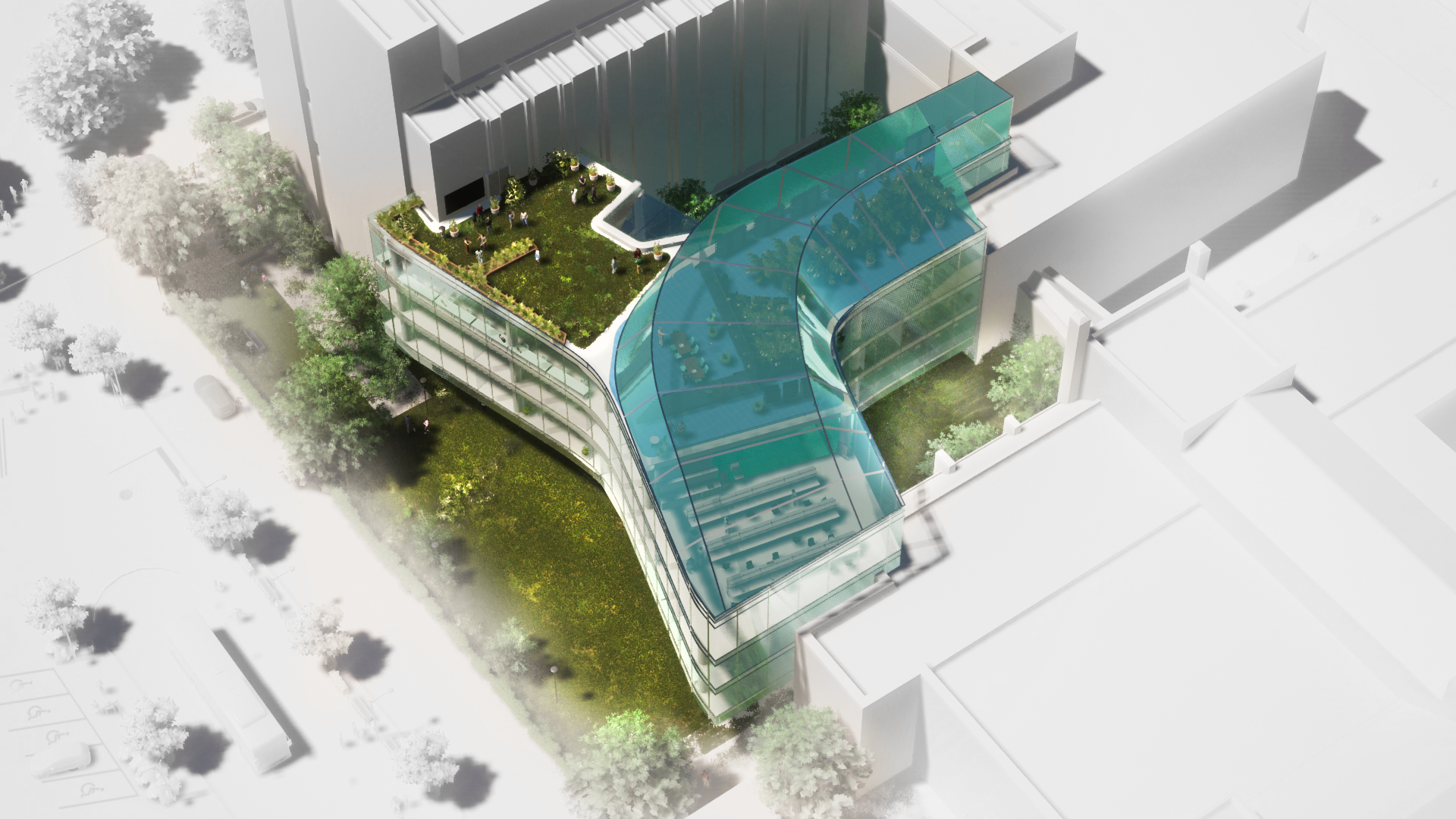

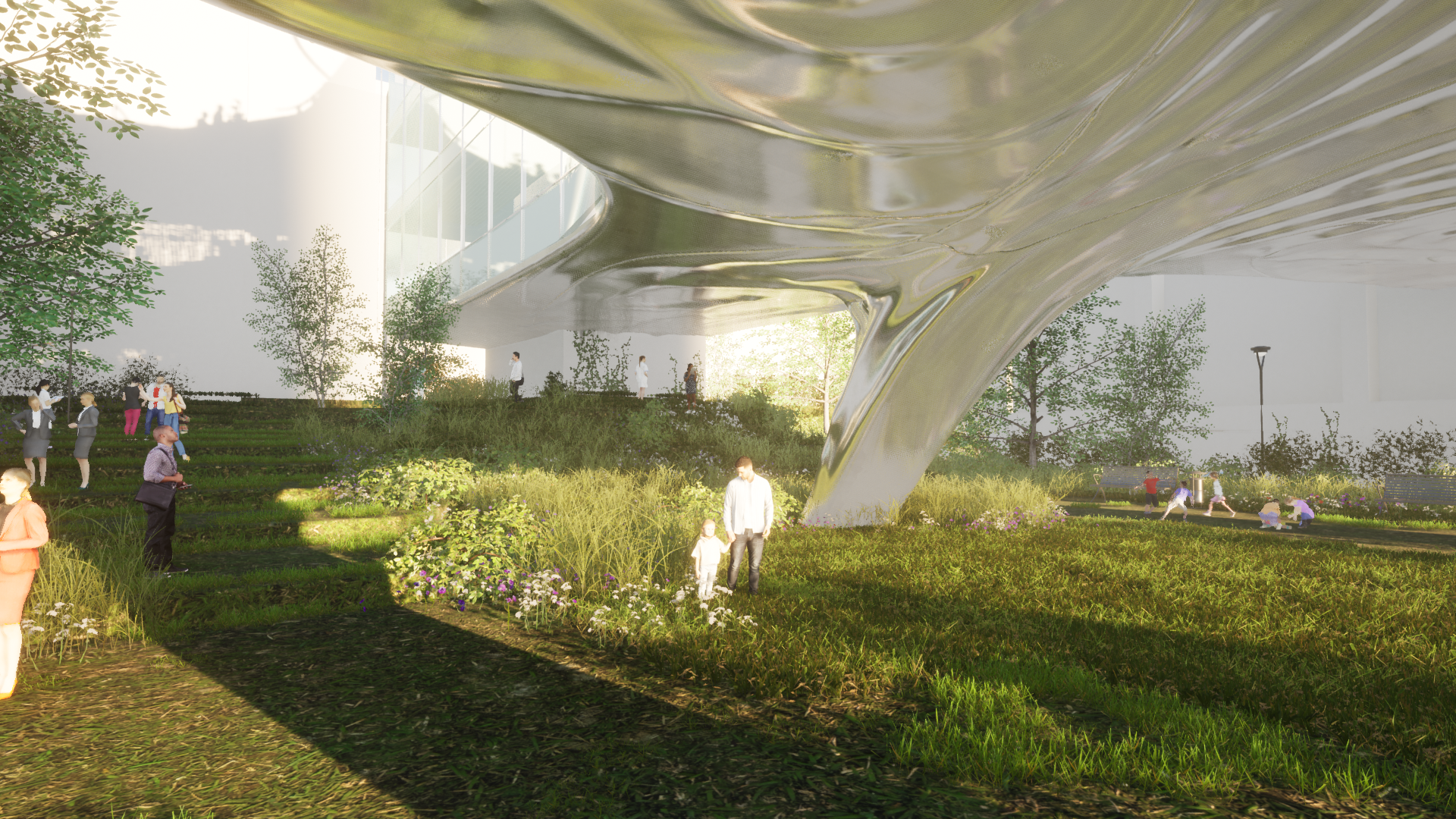

Penn Center for Innovation & Precision Dentistry

/Penn Center for Innovation & Precision Dentistry

Architectural Concept Design Leveraging Research in Robotic Fabrication and Computational Methods for Design-Engineering.

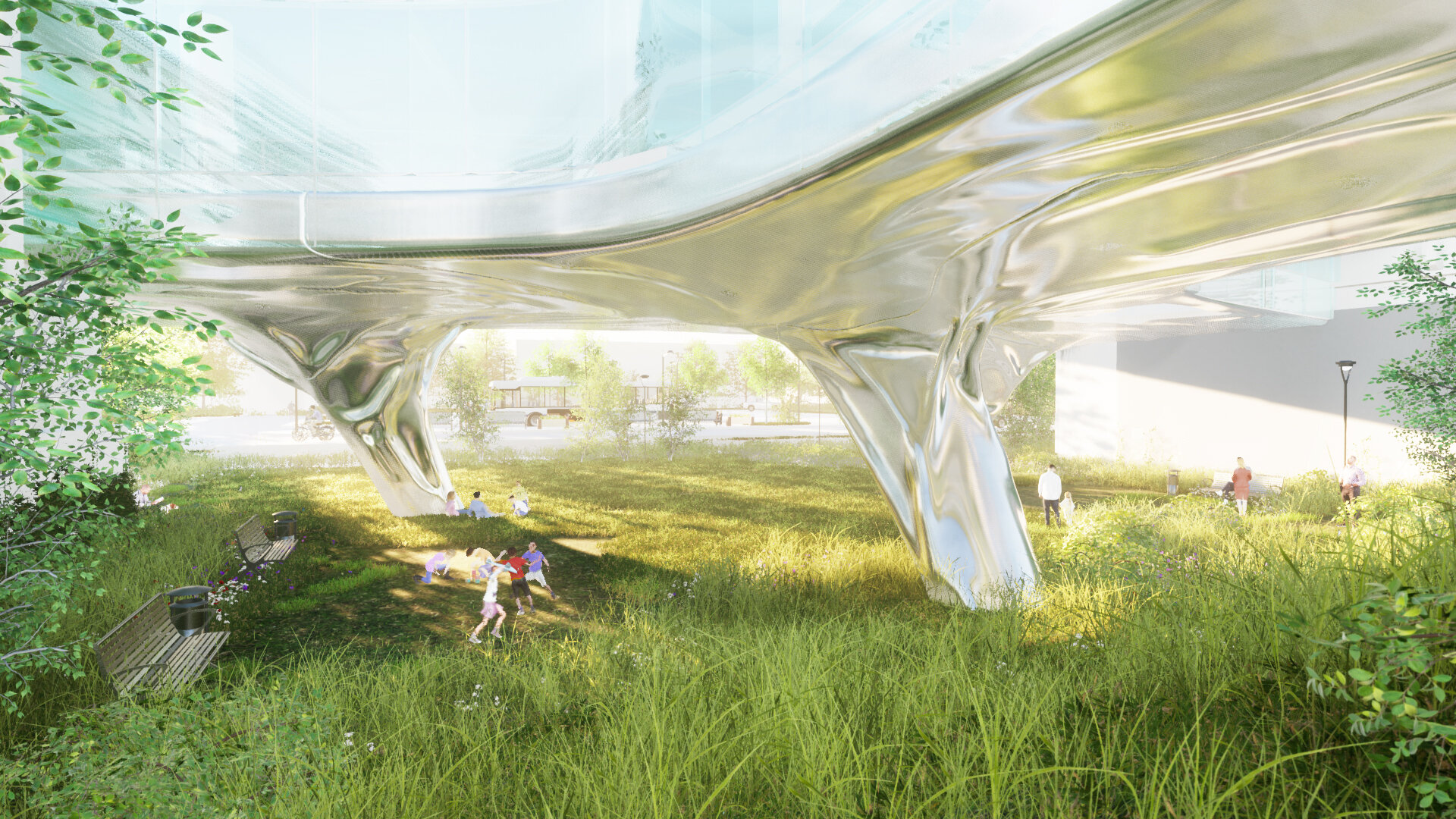

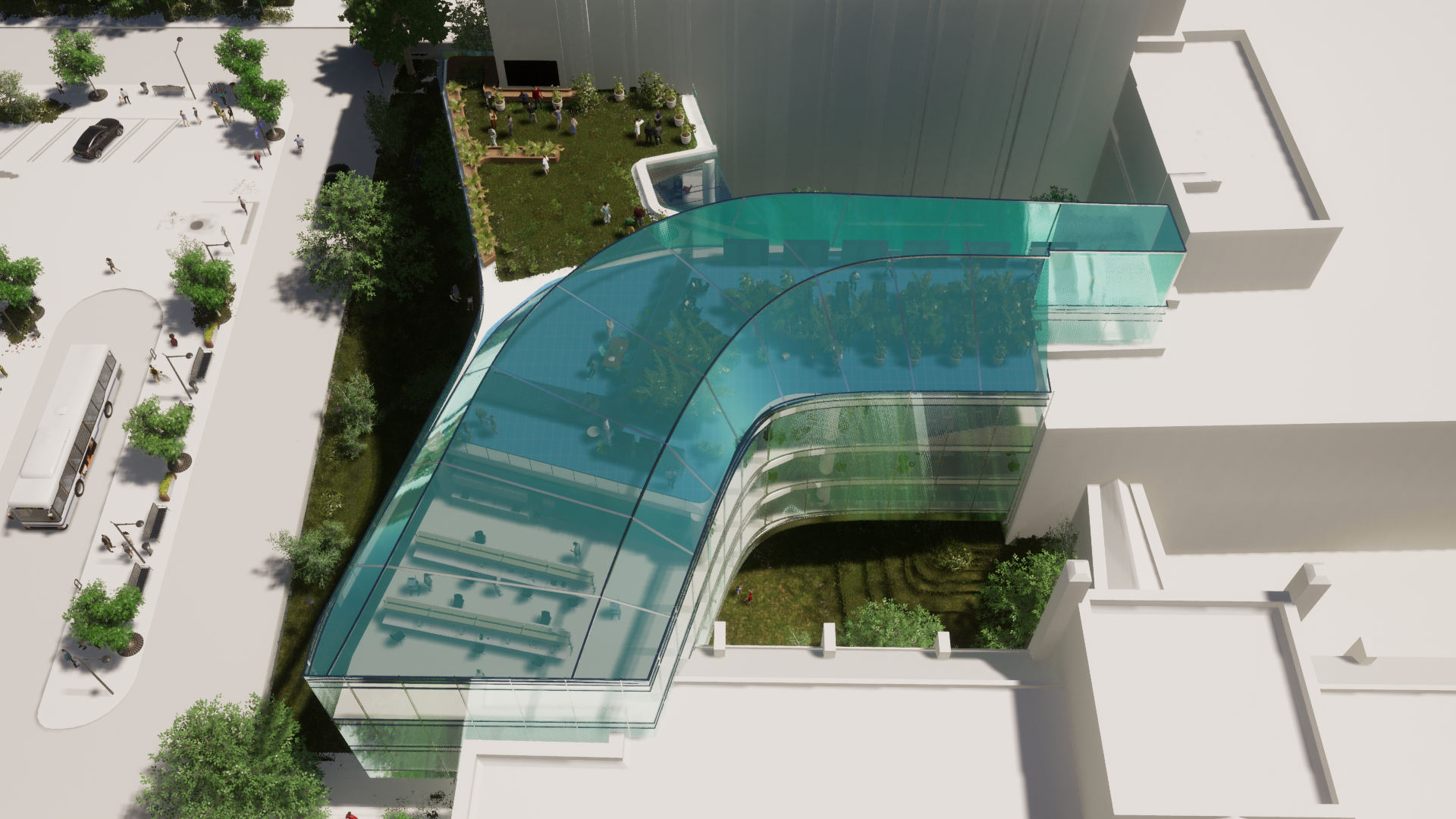

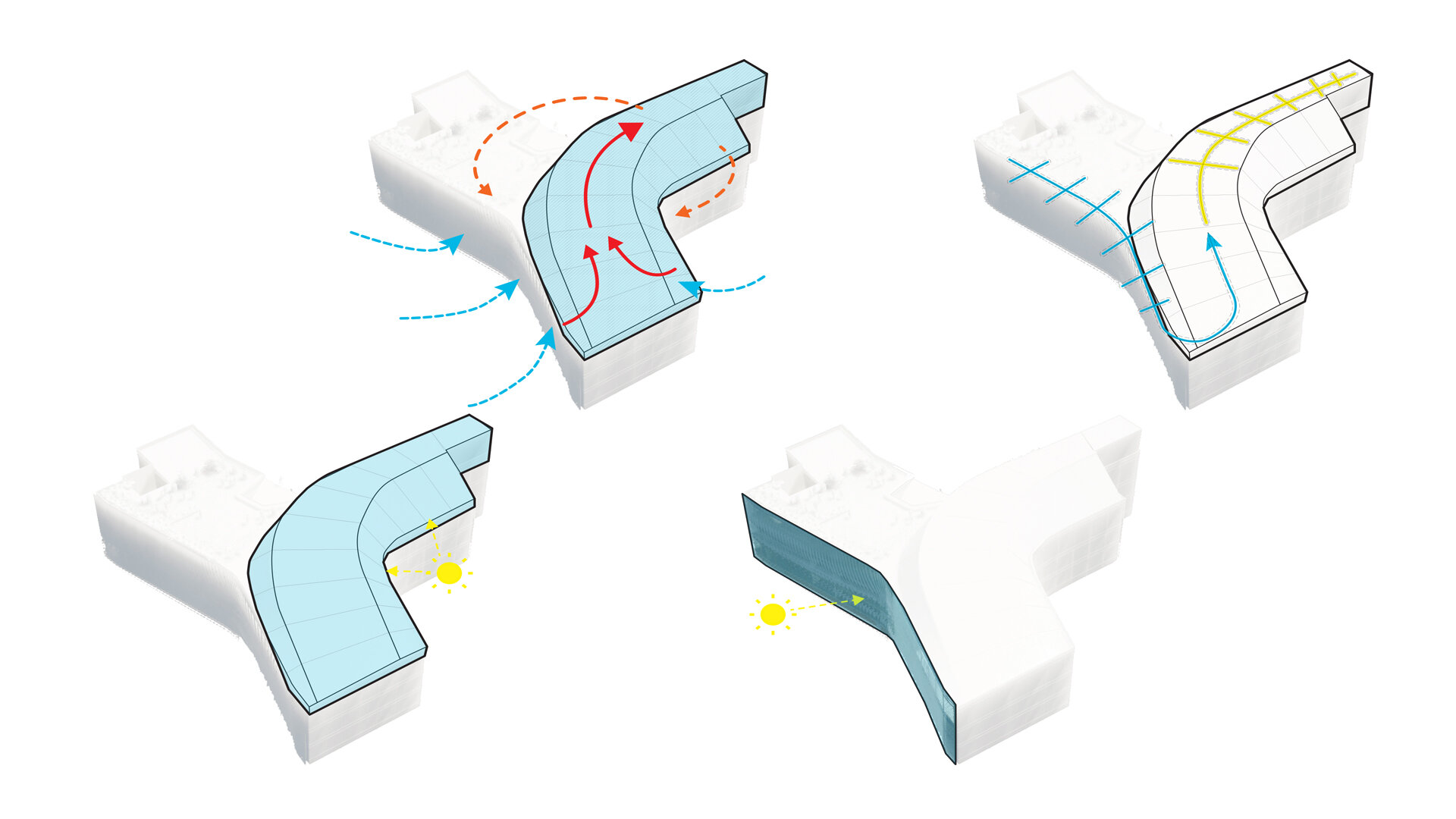

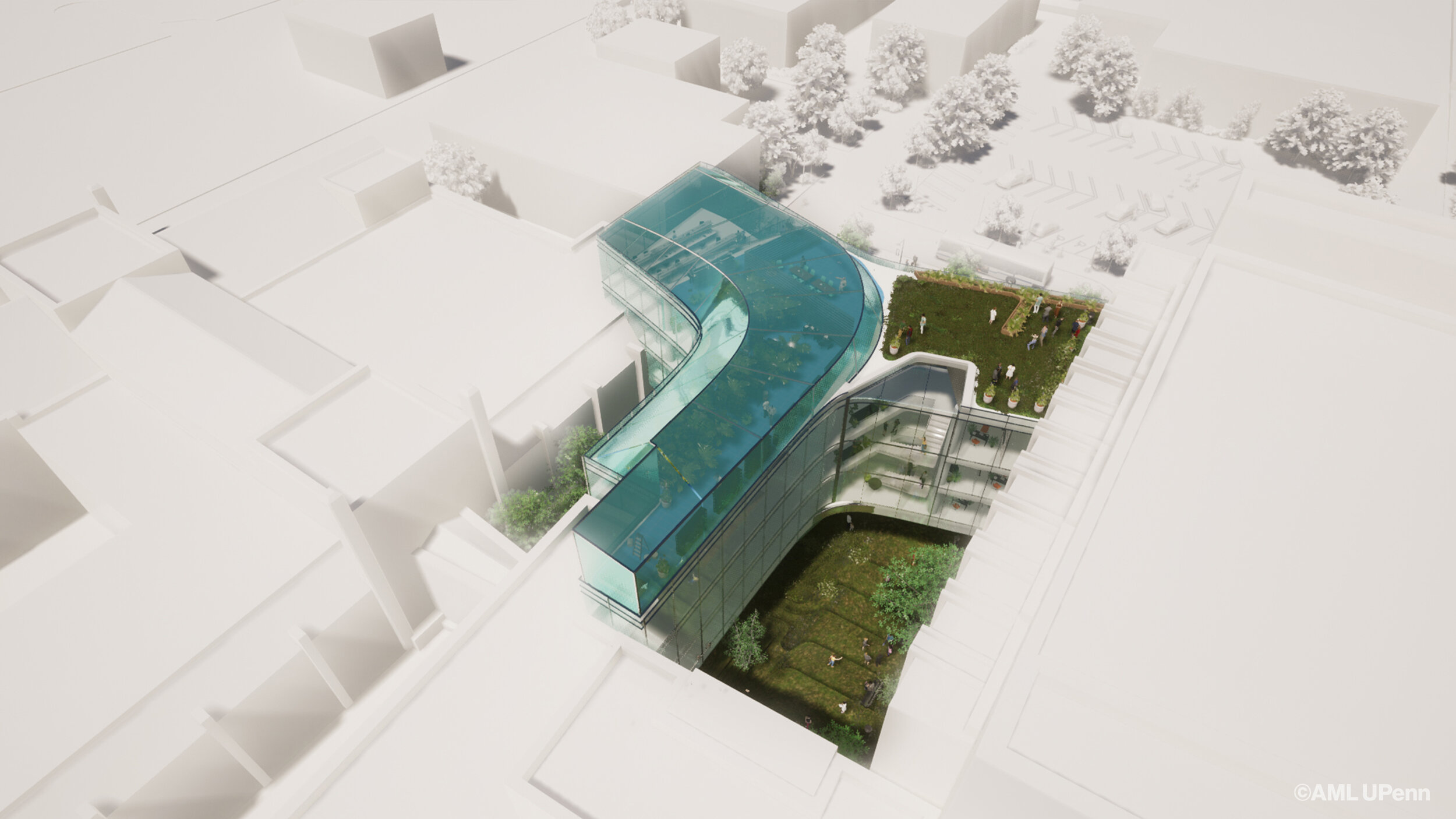

Status: Ongoing

The Penn Center for Innovation & Precision Dentistry (CiPD) will be a new hub for interdisciplinary research collaborations between faculty from Penn Dental and SEAS to advance innovation and training in Dental Medicine, leveraging their strengths for assessing and creating new technologies to study disease mechanisms and develop solutions and devices to address unmet needs in oral health. A state-of-the-art building is proposed to show-case this state-of-the-art research. Located on Penn Dental Medicine’s campus, the building operates as a 'bridge' connecting the existing Evans, Schattner Center and Levy Center buildings. Innovative design-engineering principles and robotic fabrication methods are employed to enable the building to 'float' above an existing courtyard, preserving its garden and pedestrian pathways by utilizing a custom-engineered pilotis transfer structure that also doubles as a reflective ceiling to enhance the spatial experience of the courtyard below. The building incorporates several advanced environmental design concepts, including the integration of a rooftop greenhouse research facility into the overall building's heating and cooling system, alongside passive and active environmental management technologies. Envisaged as a flexible and socially engaging space, the floors of the building consist of re-configurable lab spaces and open meeting and gathering spaces that are connected to a central atrium and stair that is in visual dialogue with the courtyard. Penn's CiPD will be an open, active and engaging building that aims to foster collaboration, new discoveries and innovation.

Architectural Concept Design:

Autonomous Manufacturing Lab, Department of Architecture, University of Pennsylvania Weitzman School of Design

Director: Robert Stuart-Smith

Design Team: Patrick Danahy

Client:

Dr. Hyun (Michel) Koo and Dean Mark Wolff, Penn Dental, University of Pennsylvania

Collaborators:

Dr. Hyun (Michel) Koo, Penn Dental, University of Pennsylvania

Ellen Neises & Julie Donofrio, Penn Praxis, University of Pennsylvania

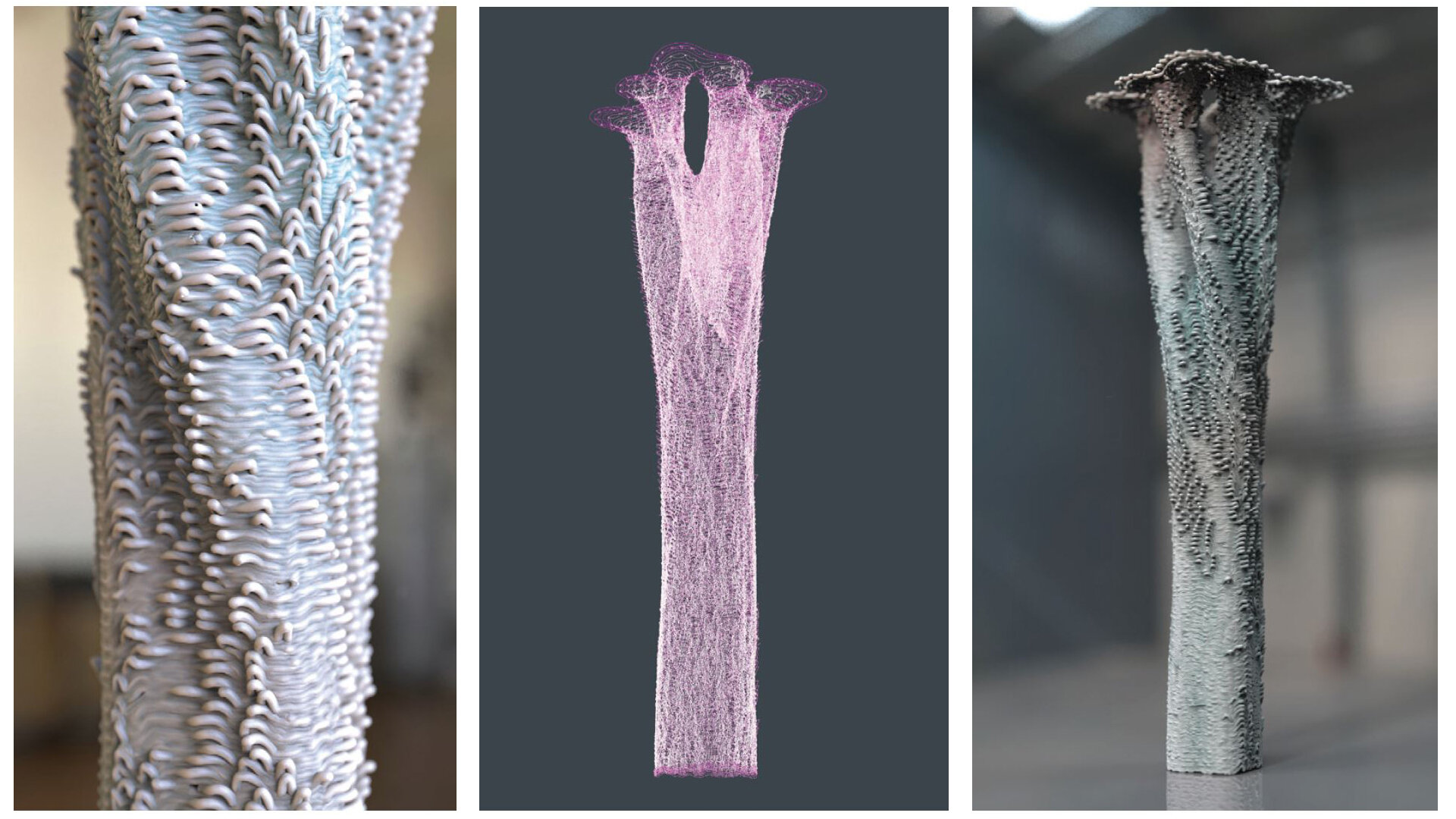

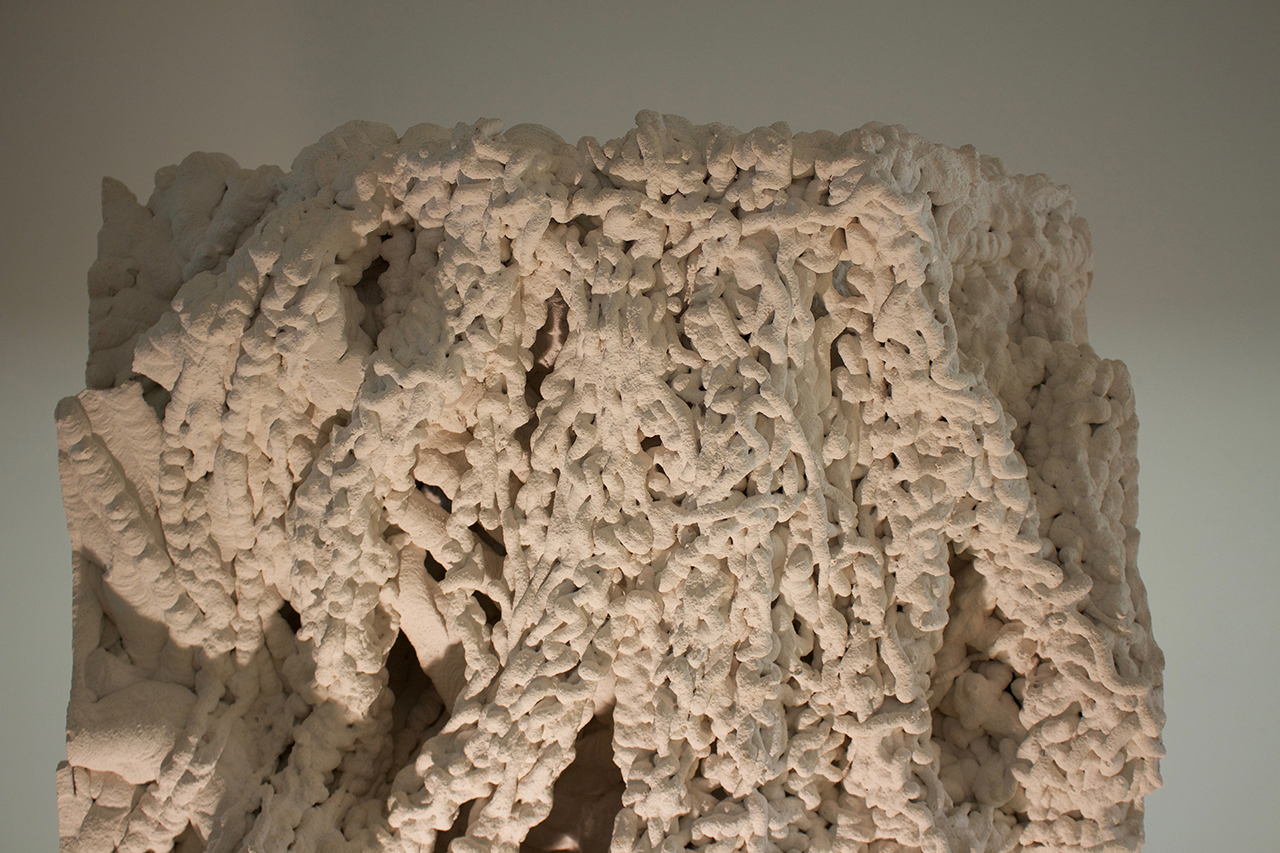

matForm & matSim: Agent-based Design, Simulation & Analysis of Material effects during Additive Manufacturing

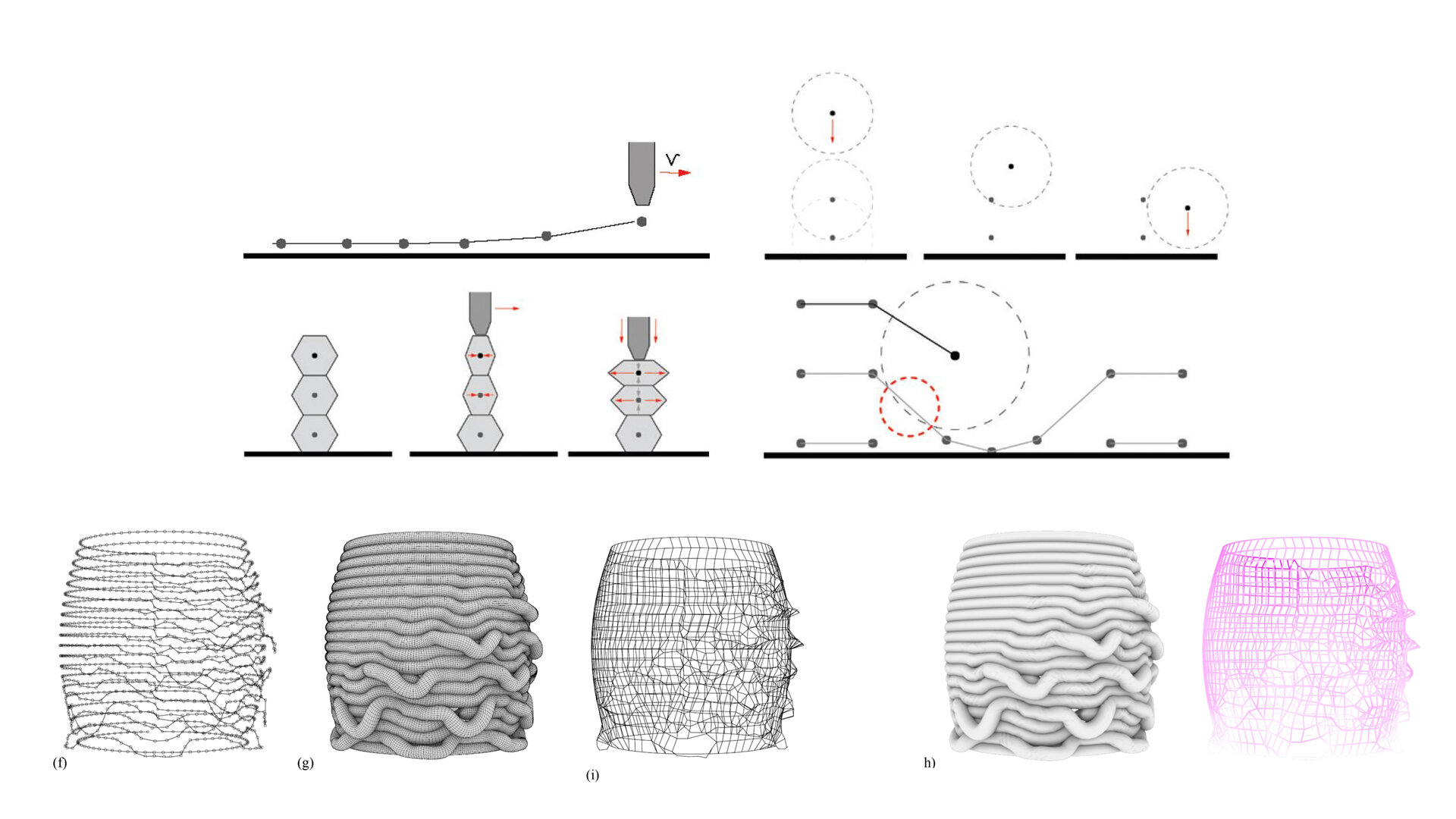

/AGENT-BASED CERAMIC ADDITIVE MANUFACTURING

Agent-based robotic extrusion and computational physics simulation method

Additive Manufacturing(AM) methods are being adopted in building construction due to their ability to provide reductions in time, cost and material waste, while offering increased aesthetic design flexibility. The most common large-scale AM method; continuous layered deposition, is typically used to create monolithic surfaces that do not take full advantage of the bespoke programmability robot manufacturing affords. While material dynamics and high-definition variable printing paths have been explored insmall-scale additively manufactured ceramics and concrete, these experiments are not easily scaled-up to building-scale assemblages, which would require means of visual or structural analysis prior to manufacture. The research addresses material formation in simulation and production through an integrative approach to design, structural analysis and fabrication. A custom software for robot extrusion tool path creation was developed that incorporates an adaptive agent-based robot deposition and physics-based material simulation method in order to leverage material dynamics relative to structural and formal design constraints to produce ornamental affects intrinsic to a developed production process. The method involved the development of two softwares; matForm to generatively design material-scale affects through custom robot tool path creation, and matSim, a material-physics simulator that outputs geometry suitable for visual and structural analysis.

Lead Researcher: Robert Stuart-Smith

Researchers: Patrick Danahy, Natalia Revelo, Sanjana Rao

topoForm#1: Generative Topological Design for Additive Manufacturing

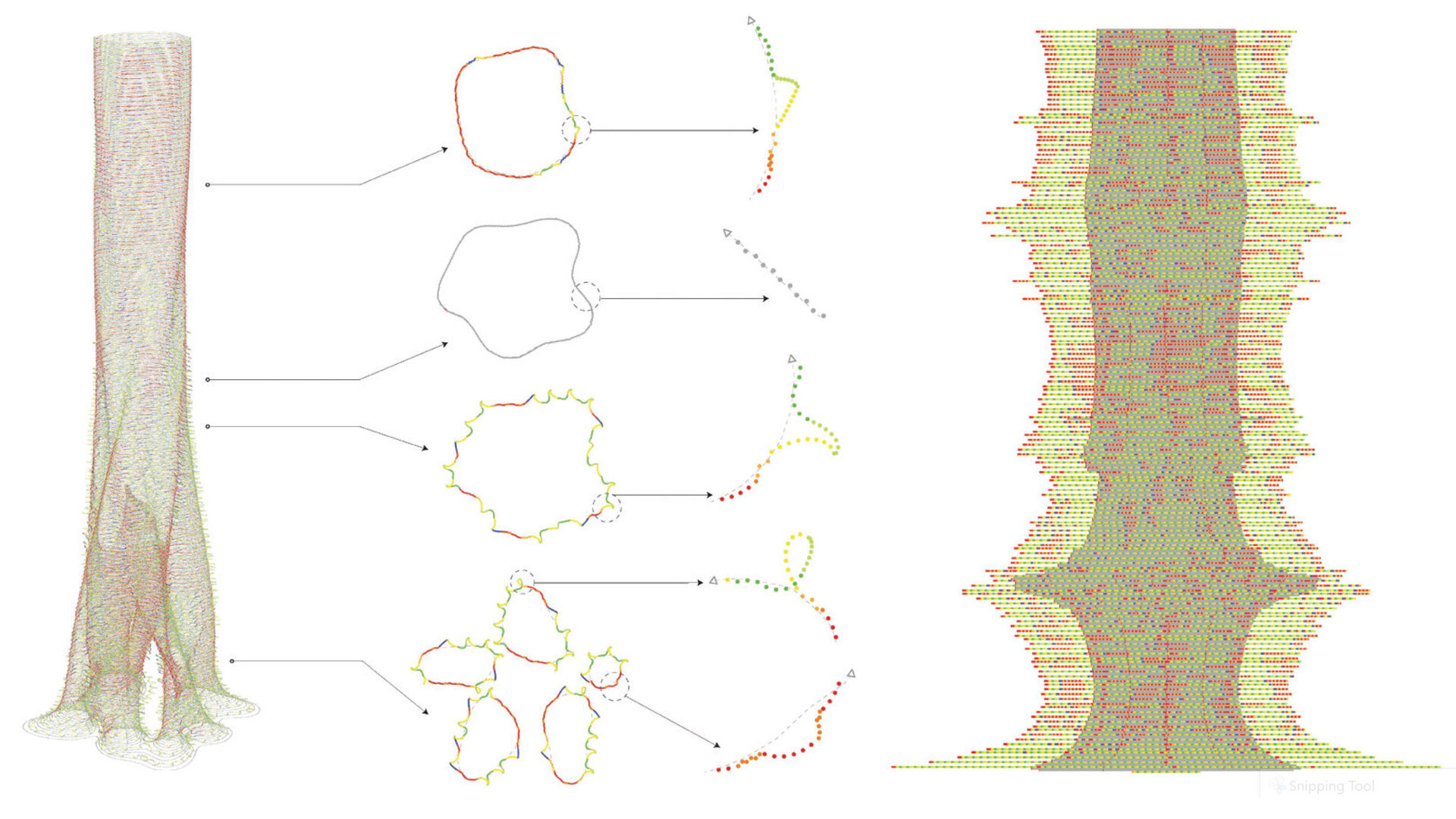

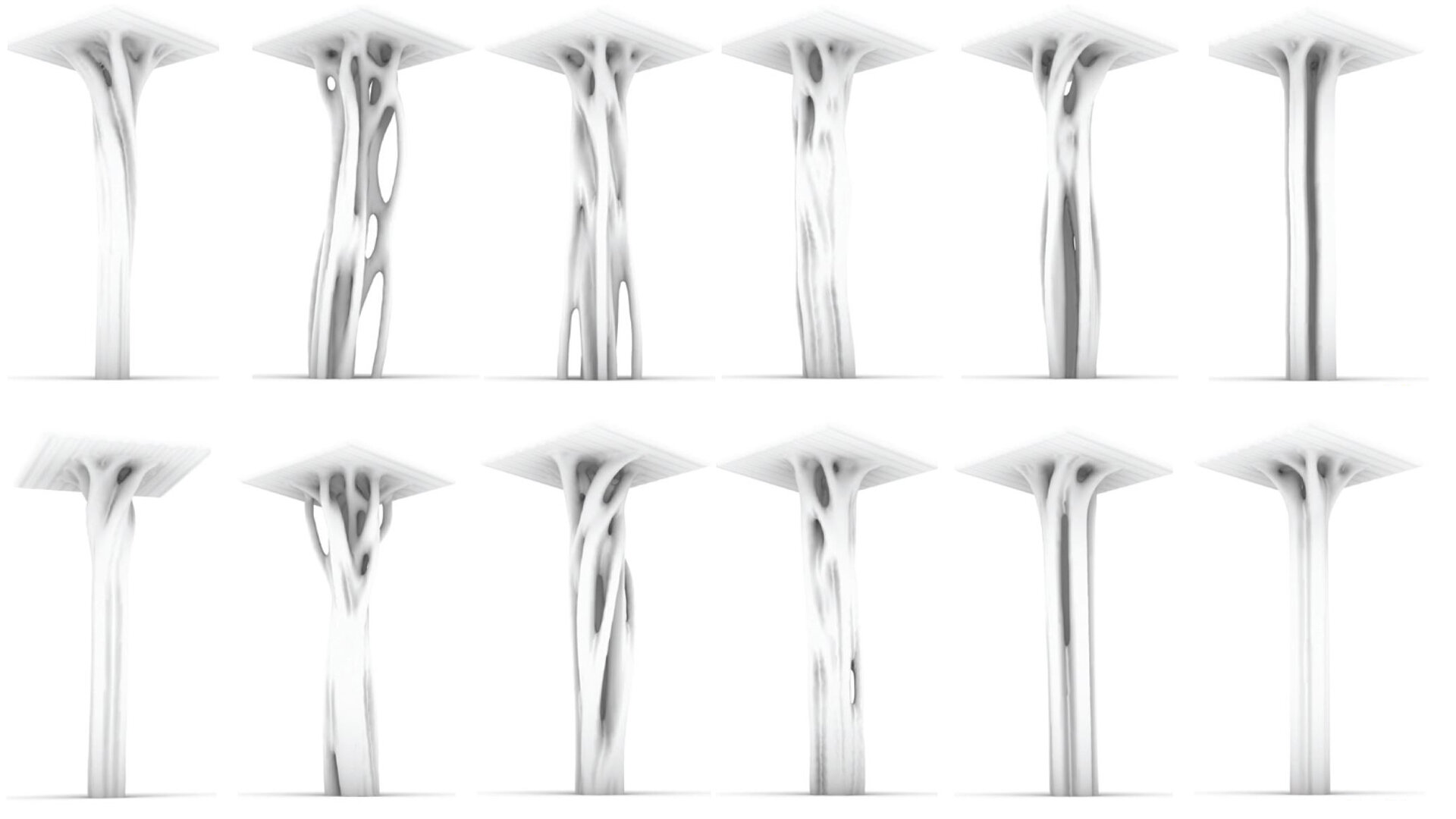

/MULTI-AGENT TOPOLOGICAL FORMATION FOR ADDITIVE MANUFACTURING

Additive Manufacturing(AM) methods are being adopted in building construction due to their ability to provide reductions in time, cost and material waste, while offering increased geometric design flexibility. This flexibility enables increases in topological complexity to provide greater structural integrity whilst reducing the material volume utilized in the manufacture of parts. This research developed a multi-manifold generative design software that is able to embed both structural and geometric optimisation within a bespoke design process that preserves algorithmic character throughout optimisation cycles.

topoForm #1 is in an evolutionary multi-agent software that develops topological design solutions for column-like elements while attempting to optimize for several structural and geometric conditions. Inspired by John Frazer’s Etruscan Column project and Richard Dawkins’ Blind-Watchmaker algorithm, topoForm #1 is both an evolutionary and generative design algorithm. topoForm #1 mixes bottom-up agent-based behavior with top-down global means of analysis and evaluation, leveraging systemic openness and design character from local agent-based interactions while ensuring agent behaviours are evolved towards performance-based results.

Lead Researcher: Robert Stuart-Smith

Researchers: Patrick Danahy, Natalia Revelo

Applied Off-site and On-site Collective Multi-Robot Autonomous Building Manufacturing (AML-UCL)

/AML-UPENN's affiliate lab, AML-UCL is undertaking research into Applied Off-site and On-site Collective Multi-Robot Autonomous Building Manufacturing. A UK EPSRC funded research project that will develop capabilities for 3D BIM-adaptive autonomous multi-robot: data collection, off-site fabrication, on-site construction. The project is a collaboration between the AML at University College of London, Imperial College, and industrial partners: Skanska, Mace, MTC, and Kuka.

Principle Investigator: Robert Stuart-Smith

Co-Investigators: Vijay Pawar, Mirko Kovac, Jacqueline Glass

Additive Manufacturing: Behavior-Based Concrete Deposition

/SITUATED FABRICATIONS UNIVERSITY OF INNSBRUCK | 2016

Innsbruck, Austria

Technology Seminar: Robotic Fabrication

situatedFabrications explores design through generative fabrication methods that utilise situated robotic protocols to engage in real-time sensing and fabrication behaviours. As a behaviour-based approach to 3D Printing in concrete, robot operations negotiate pre-determined design intention, real-time feedback and encoded algorithmic design behaviours in order to produce novel Additively Manufactured works. The seminar focused on the design and prototyping of a concrete architectural screen partial mockup. Digital and physical processes will aim to embody spatial, formal and material affects that arise from their integrated design and production process. Messy and engaging; these processes involve novel forms of participation and in-direct control, and aim to challenge the explicit nature of established robotic fabrication procedures.

Visiting Professor: Robert Stuart-Smith

Academic Chair: Marjan Colletti

Academic Staff:

Johannes Ladinig, Georg Grasser, Pedja Gavrilovic,

students:

Andreas Auer

Monique banks

Marcus Bernhard

Thomas Bortondello

Marc Differding

Christophe Fanck

Konstantin Jauck

Emanuel Kravanja

Jil Medinger

Sonia Molina-Gil

Pol Olk

Michael Schwaiger

Mario Shaaya

Melina Stefanova

David Stieler

Theresa Uitz

Matthias Vinatzer

Alexandra Zeinhofer

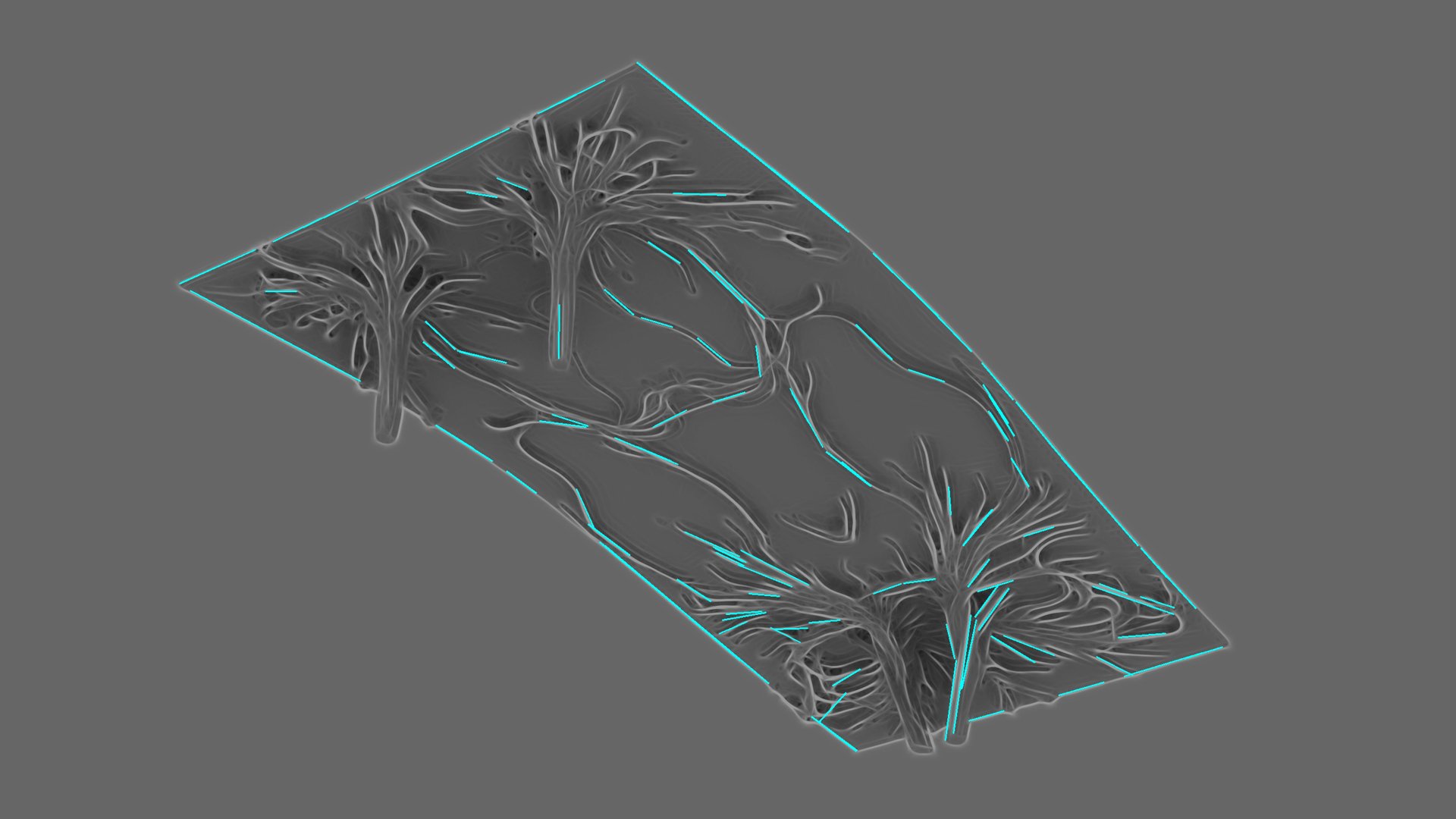

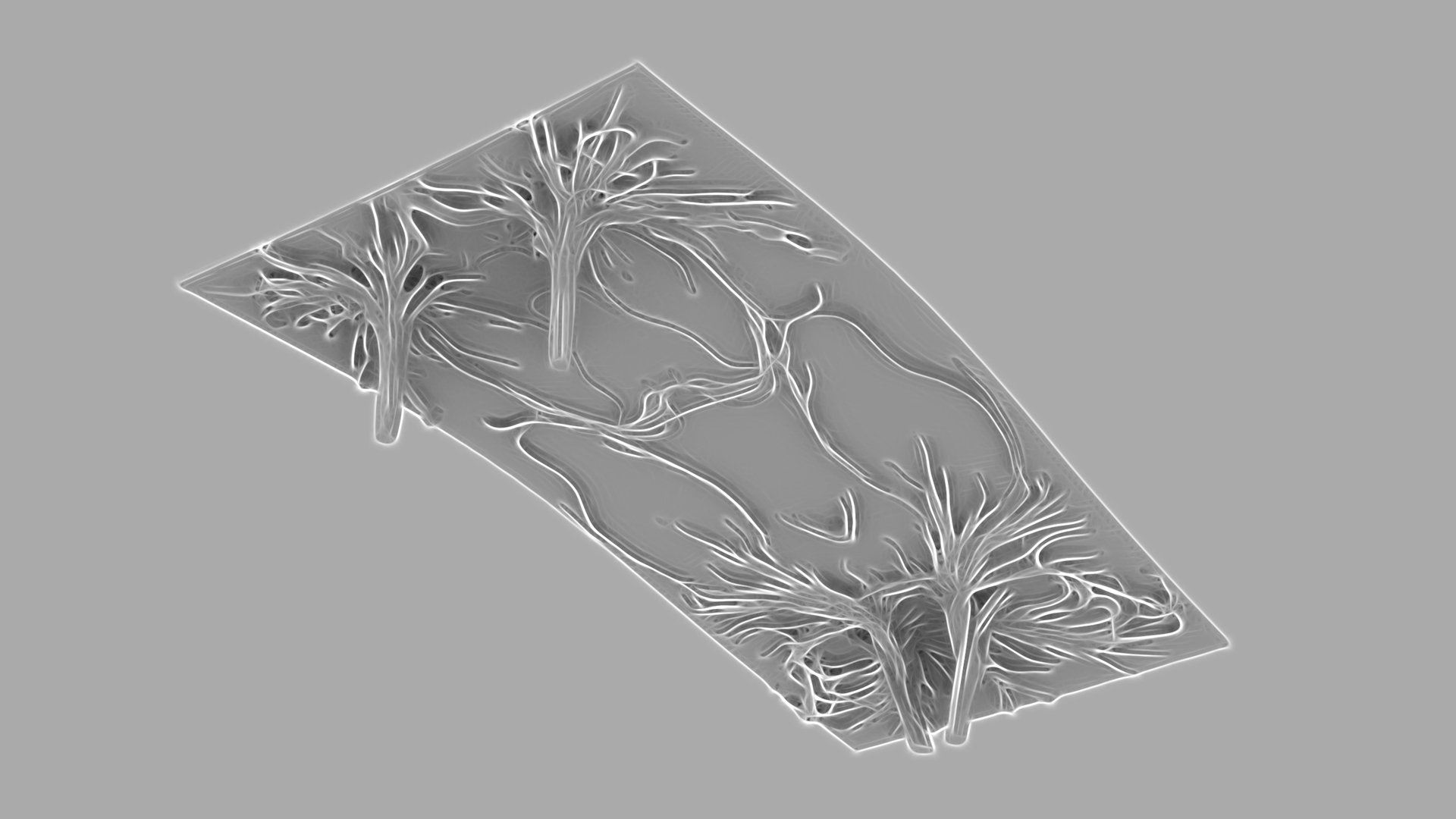

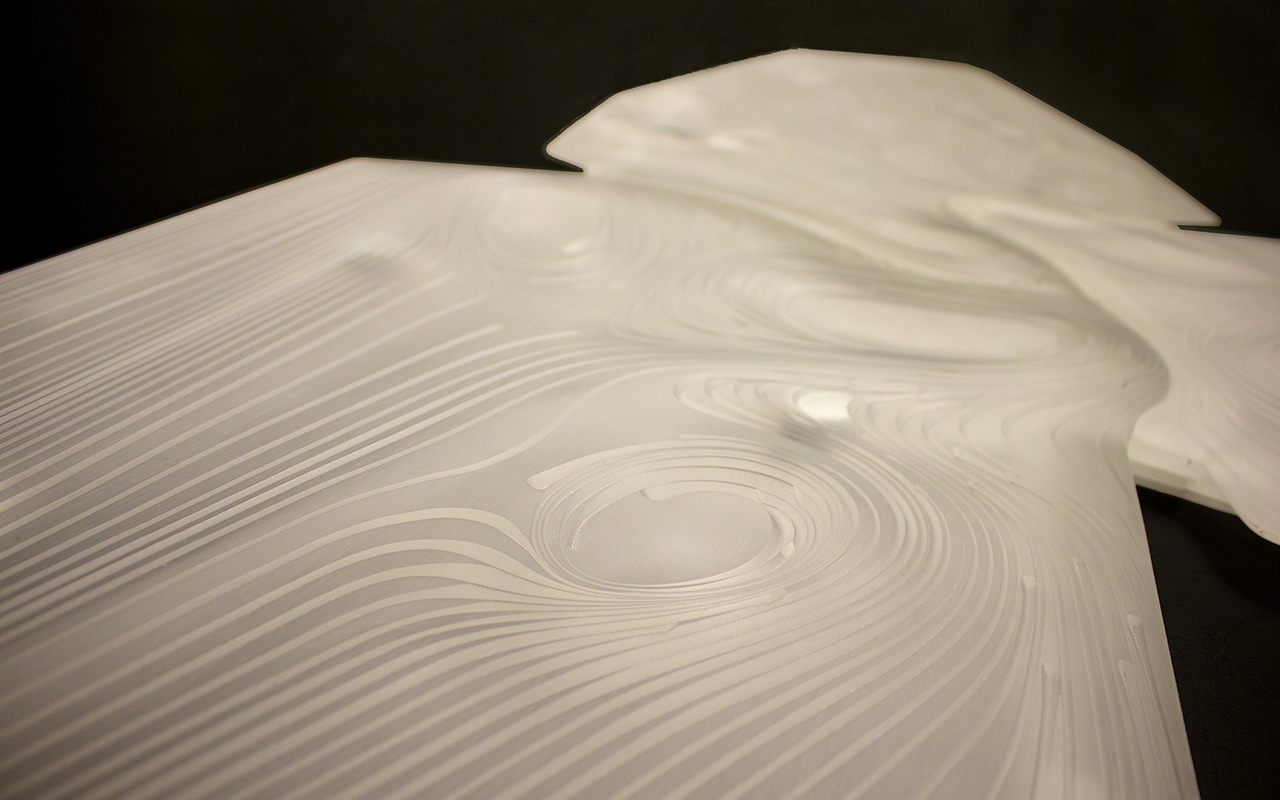

Real-Time Subtractive Manufacturing

/SwarmRelief forms part of a series of works exploring Behavioural Production; which seeks to compress design and production within one creative process. The relief is designed partially through generative multi-agent computational processes executed on a computer, and partially through algorithms executed in real-time directly within the fabrication process. This real-time code determines the precise behaviour of a CNC machine’s trajectory and velocity in which it carves out a series of curves. These curves are qualitatively enhanced through the algorithms engagement with the machining process that differentiates its behaviour throughout time and space. The overall affect of the piece arises from this process and describes a detail of fabrication not easily replicated without engagement with the real-time operation of the machine. Fusing design and production within one creative process opens up design freedoms not possible through computational design processes alone, and enables design to embrace production contingencies such as reducing machine-time as a productive constraint that drives competitive innovation within design.

Research Director: Robert Stuart-Smith. Research Team: Maria Chiou