P2P Site-less House — Sculpture Habitacle: The design, robotic fabrication and construction of a pre-cast house

/Studio Robert Stuart-Smith, Weitzman School of Design | University of Pennsylvania

Collaborating Partner: Cemex Global Research HQ, Switzerland

Guest Professor: Dr. Masoud Akbarzadeh

TA: Ramon G Pena Toledo, Workshop Assistant: Mohammed Bholsanni

701 M.Arch Design Studio

Students: Musab Badahdah, Ce Li, AahanaMiller, Madelyn Moretta, Kunil Paik, Yunxiu Peng, Mary Stephens Swysgood, Ali Tabatabaie Ghomi, Yijia Wang, Morgan Welch, Xiaoyu Zhao,

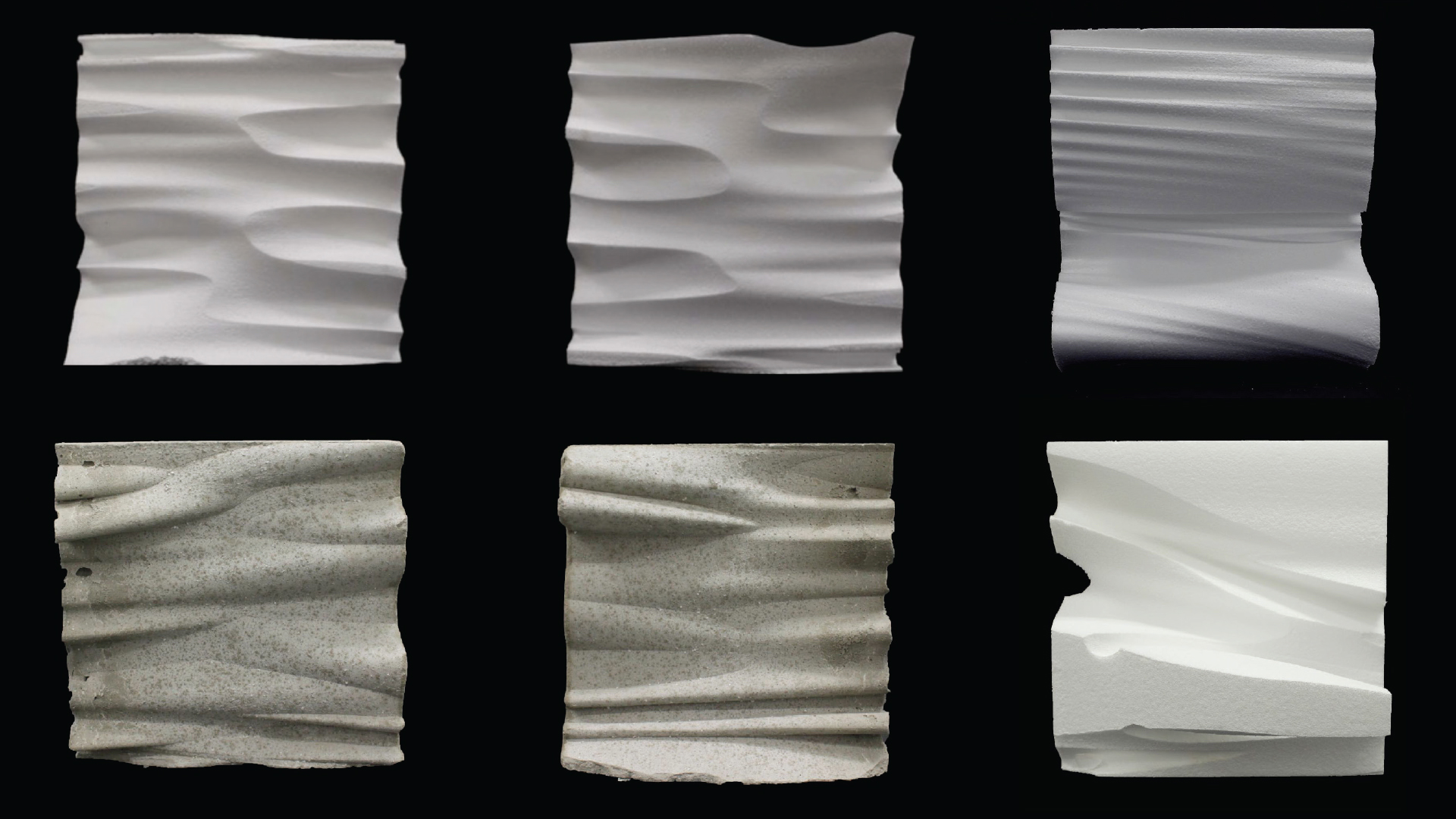

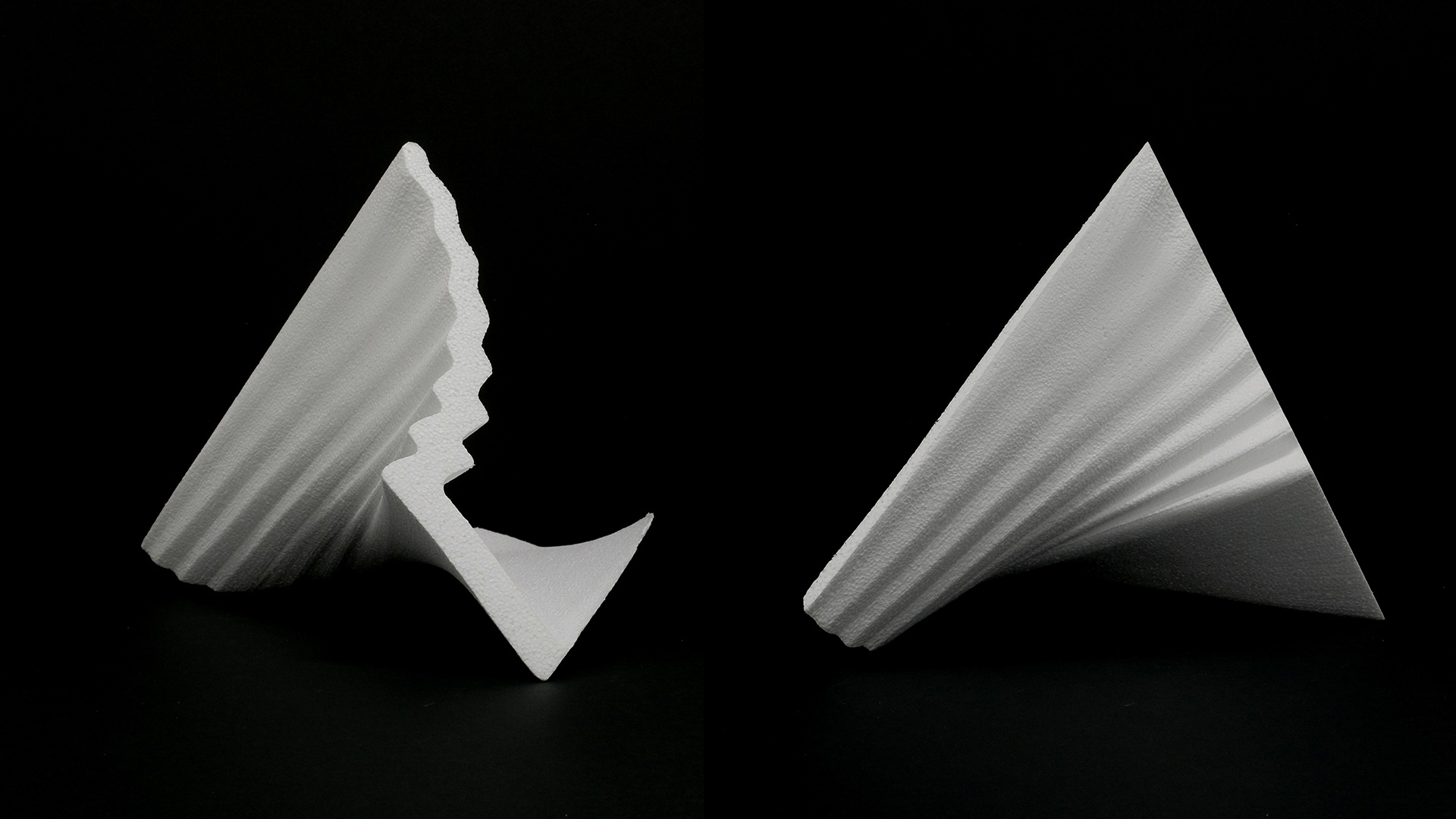

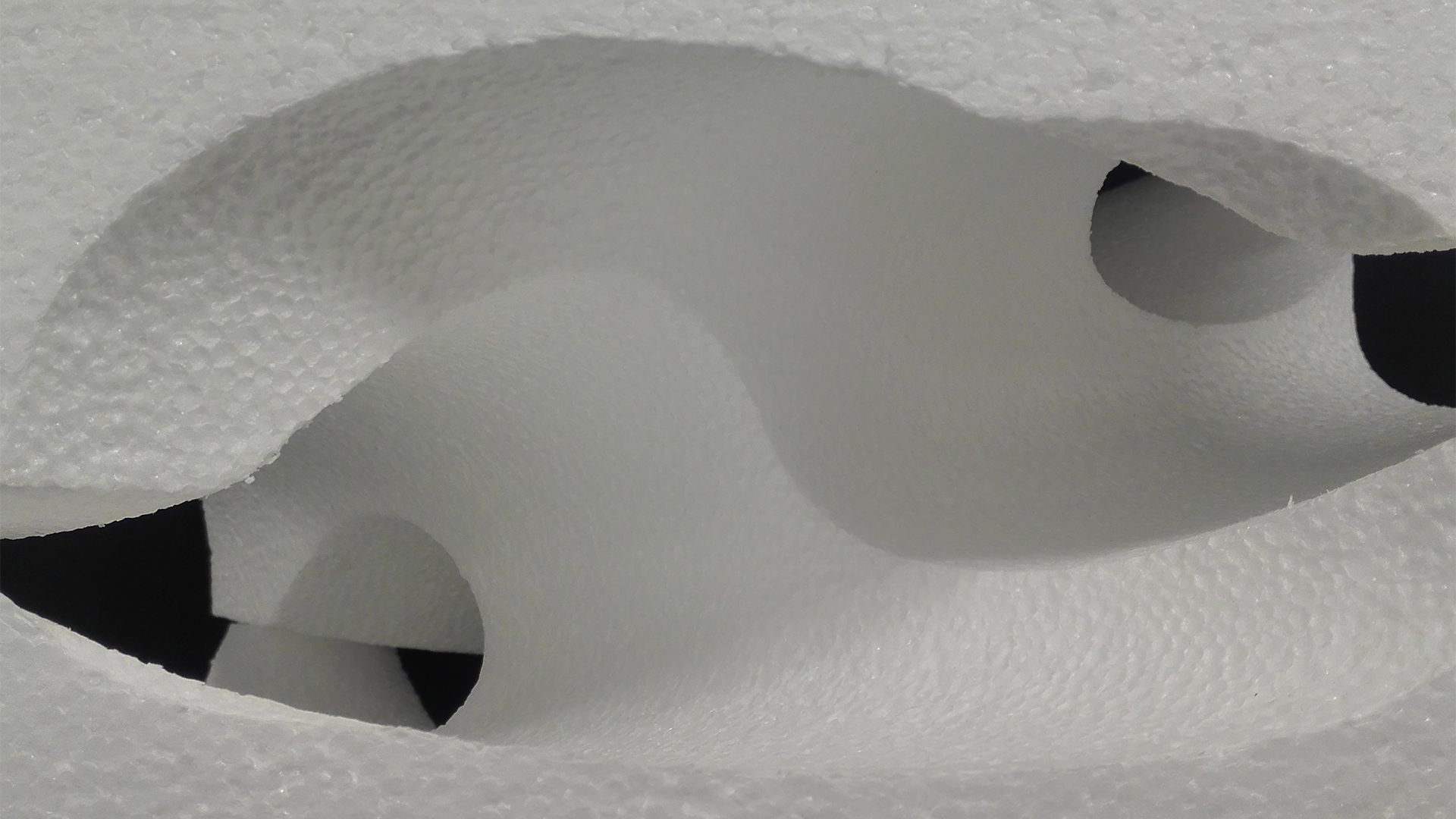

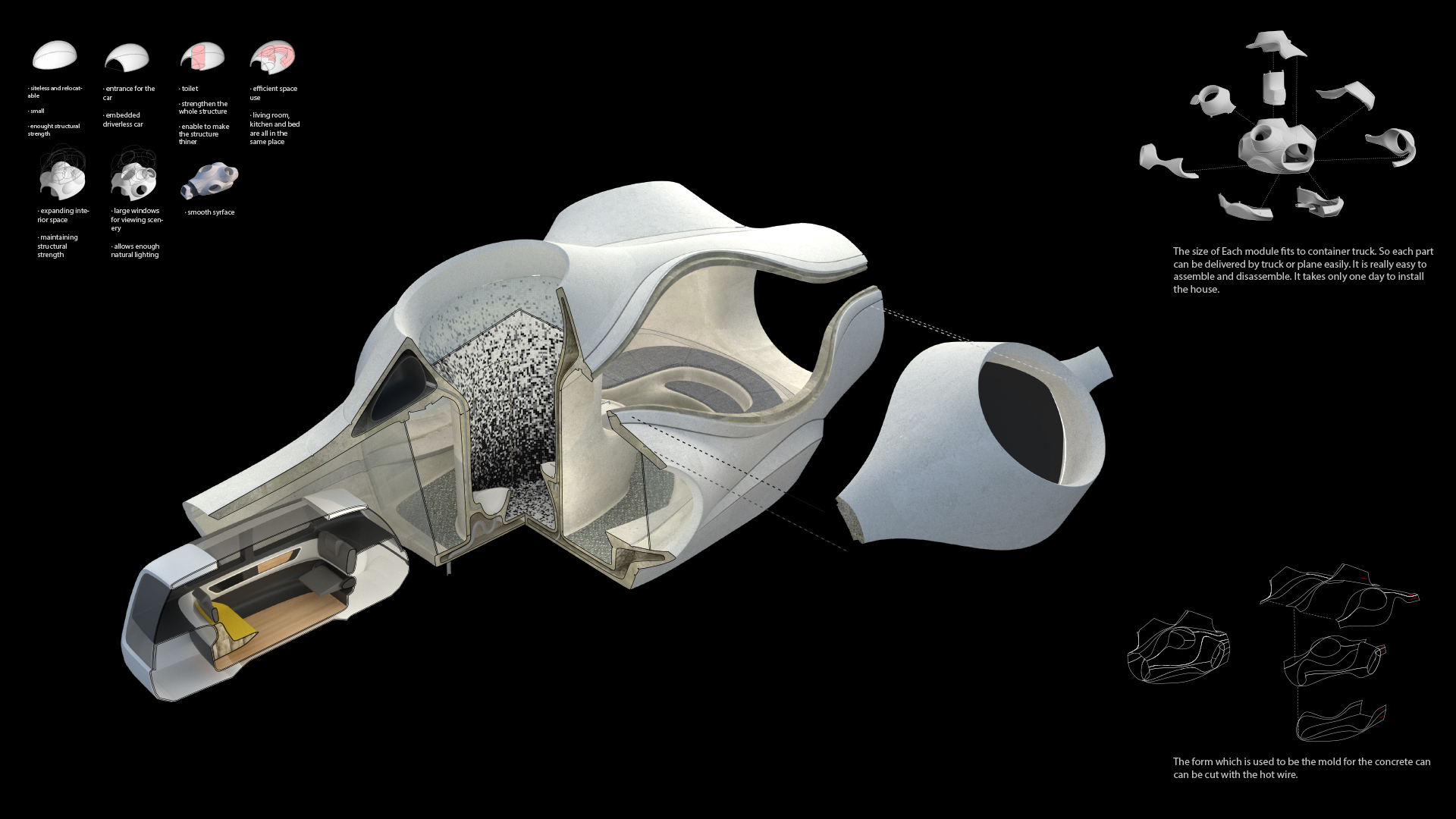

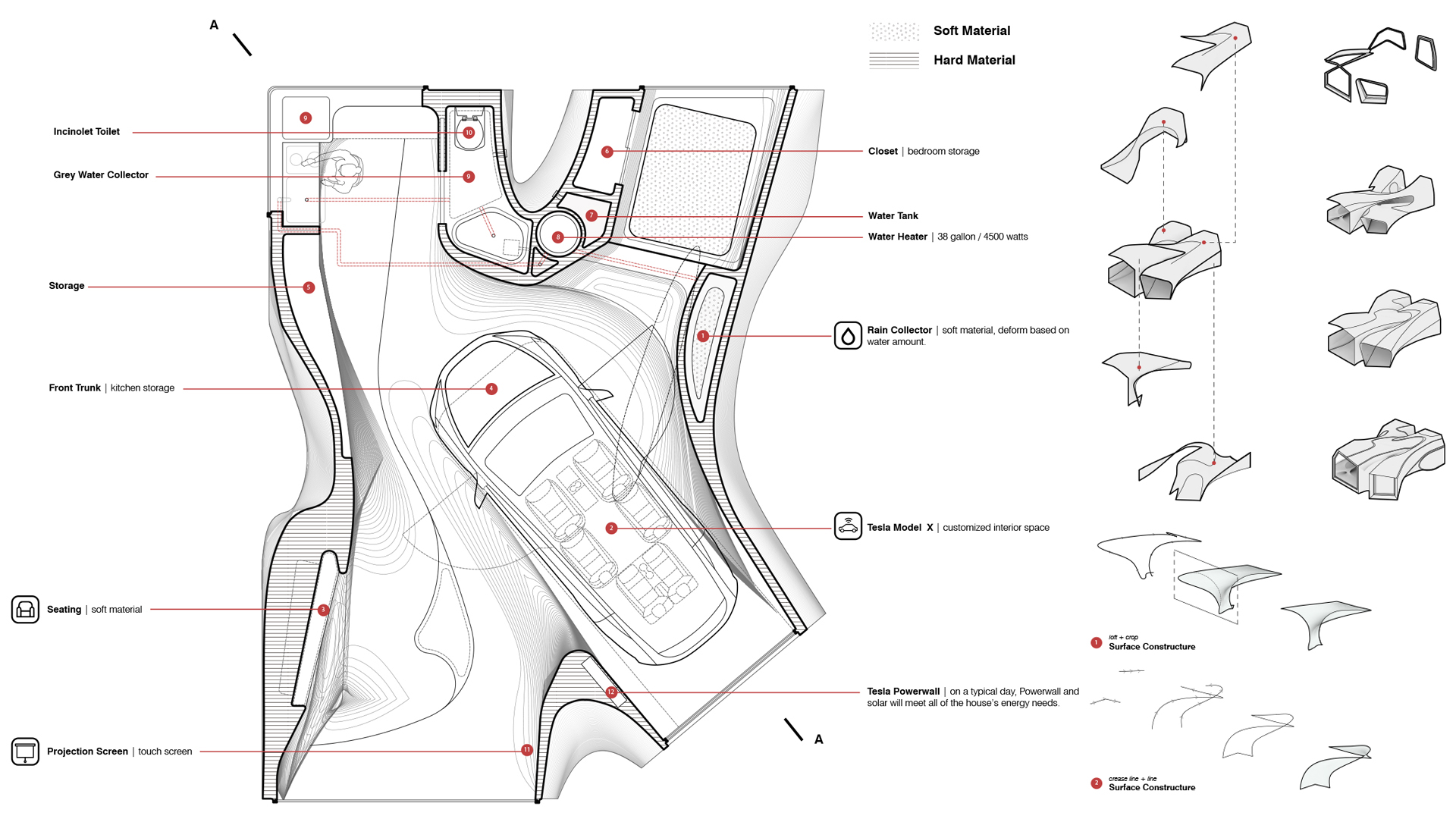

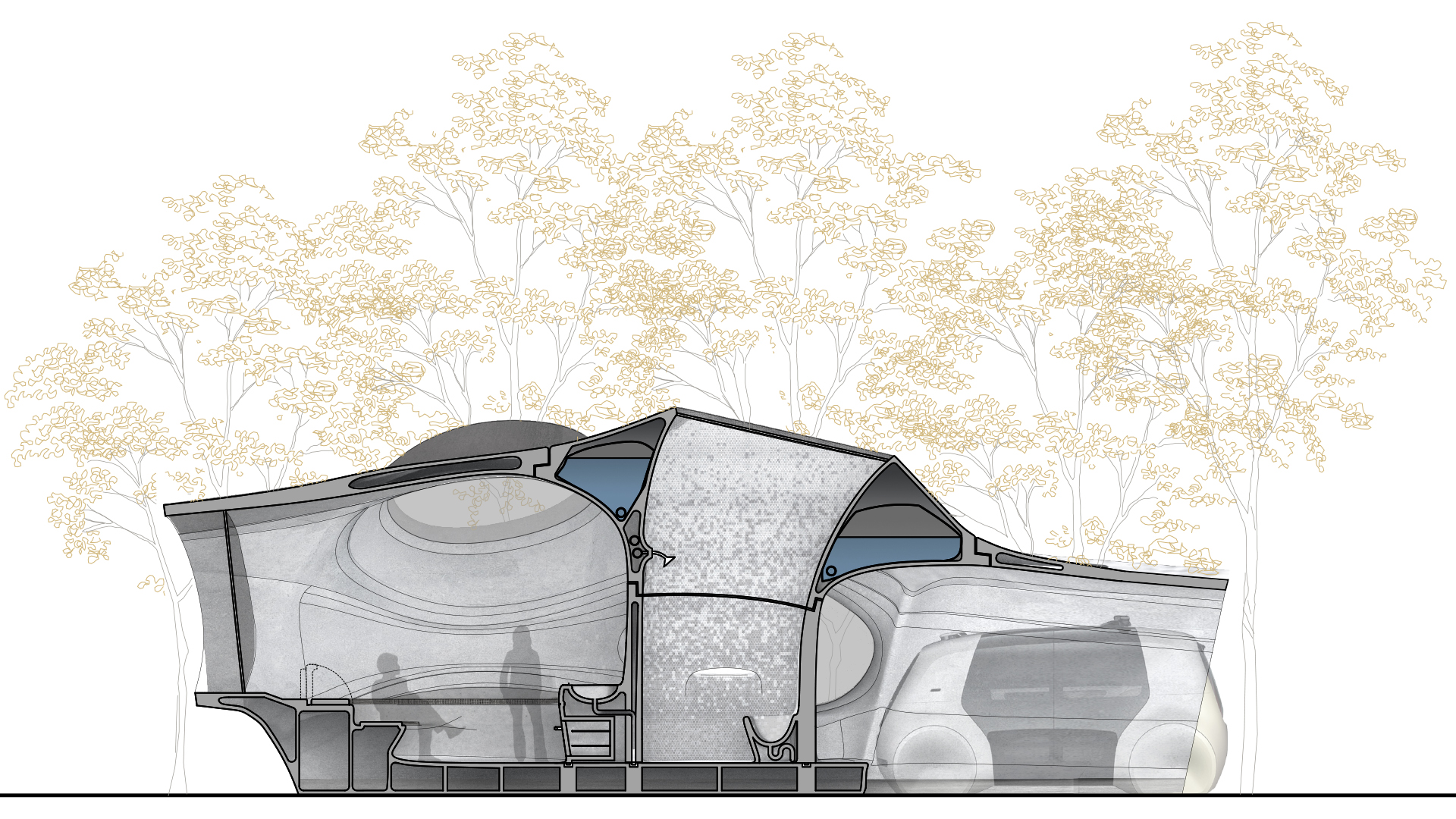

P2P Site-less House — Sculpture Habitacle enabled students to gain first-hand experience in robotic manufacturing within Penndesign’s new Robotics Lab while collaborating with concrete company Cemex on the use of robotic hot-wire cut EPS foam as formwork for the casting of ultra thin, complex cavity concrete. Students developed ideas for a robotically fabricated precast concrete house that will be continued into the Spring Semester as a technical fabrication seminar, allowing the work to be further developed into the construction of a 1:1 prototype house that will be constructed later in the year.

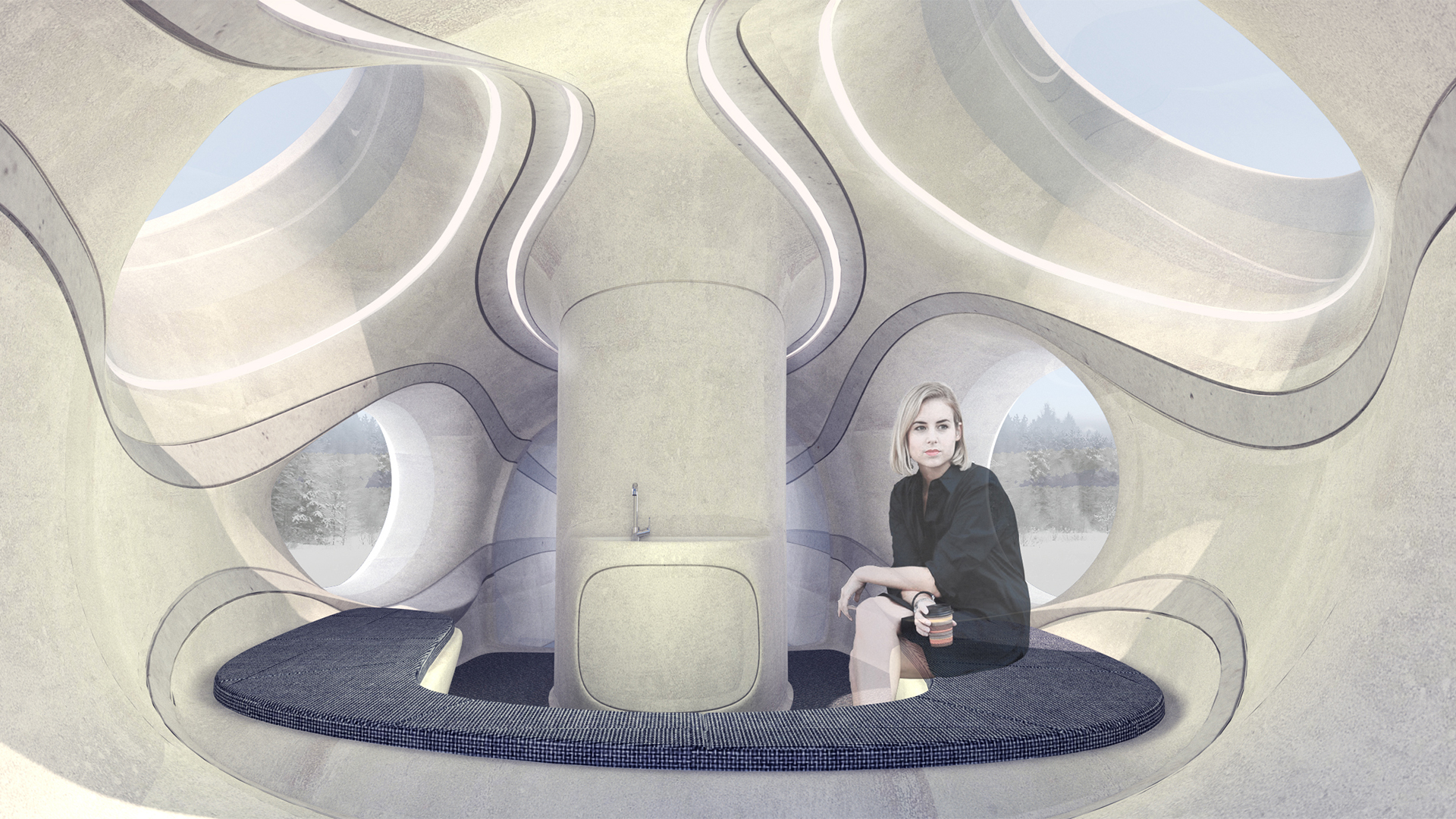

Conceptual design proposals aimed to orchestrate geometrical, formal and material affects that were developed in parallel through hands-on experimentation with Robot Hot-Wire cut EPS foam. House designs were constrained to 350 square feet. At such a small scale, the equipment and technical functions of a house are disproportionately large relative to architectural space, and can easily be too influential in many design decisions. The studio countered this by exploring design through the lens of Andre Bloc’s Sculpture Habitacle (Habitable Sculpture) questioning the functional and formal typology of the house and advocating for a non-functionalist architecture that leverages robotic production processes for design expression.

The studio explored the idea of a Peer-to-Peer shared home that can be adapted to a range of uses. The suburban house has changed little since Levittown’s construction in 1951. Levitt & Sons Inc’s first suburb offered a model of housing grounded in a social, economic and technological past, one that leveraged mass production and advocated industrial and social homogeneity. While Levittown was designed for the nuclear family (a married couple with children) who privately owned their house and car, today only 24.1% of households in the US support nuclear families. With the immanent rise of driverless car technologies and google-maps satellite navigation, the importance of the physical street address has diminished, with a ‘pin’ now providing sufficient information for one to arrive successfully at any destination. Such effortless mobility challenges existing urban models of housing by de-emphasizing location, and instead prioritizing travel time and serviceability. Providing a house can receive serviced deliveries, it could be located anywhere. With urban, suburban, rural and wild land-use constantly in flux, there persists a substantial quota of under-utilized land available at any one time. There is a social and economic opportunity for on-demand real-estate to make use of this land, providing such ventures can operate without long-term ownership or utility arrangements that would involve substantial site-specific investment. A relocatable house might help alleviate temporary housing short-falls and by its nature could also provide a seminal example of sustainable design through its re-use of wasted space, and a Design-For-Disassembly approach to architectural tectonics. While the motor car is historically considered an external object separate to the house, the studio also speculated on the role and integration of driverless cars in the home and looked for symbiotic relationships between the house and the car: operationally, formally and spatially.